Over the years I have ported my HopeRF RFM9X(Now a generic Semtech SX127X ) Windows 10 IoT Core (May 2018) library to .NET microFramework(May 2018), Wilderness Labs Meadow(Jan 2020), GHI Electronics TinyCLR-OS(July 2020), .NET nanoFramework V1(May 2020) and .NET Core(Aug 2021).

All this madness started because I wasn’t confident the frequency calculation of the Emmellsoft Dragino.Lora code was correct. Over the last couple of years I have also found bugs in my Transmit Power, InvertIQ RX/TX with many others yet to be discovered.

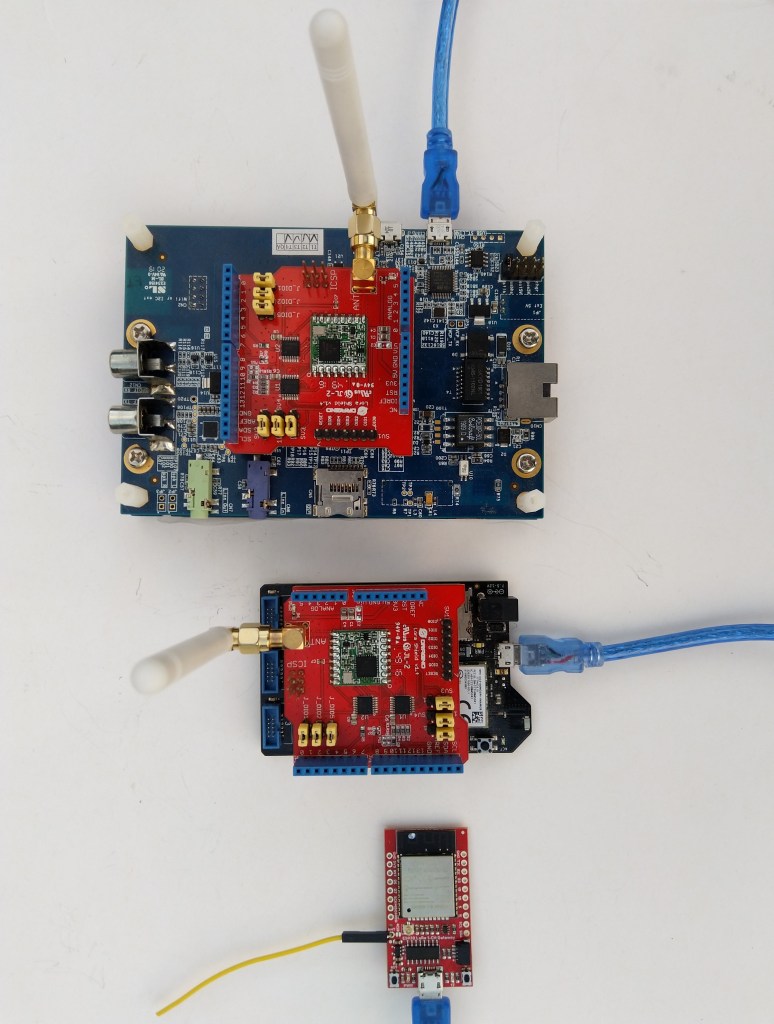

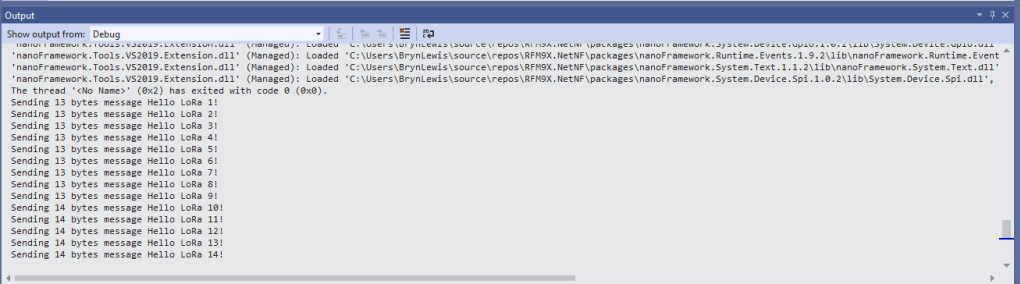

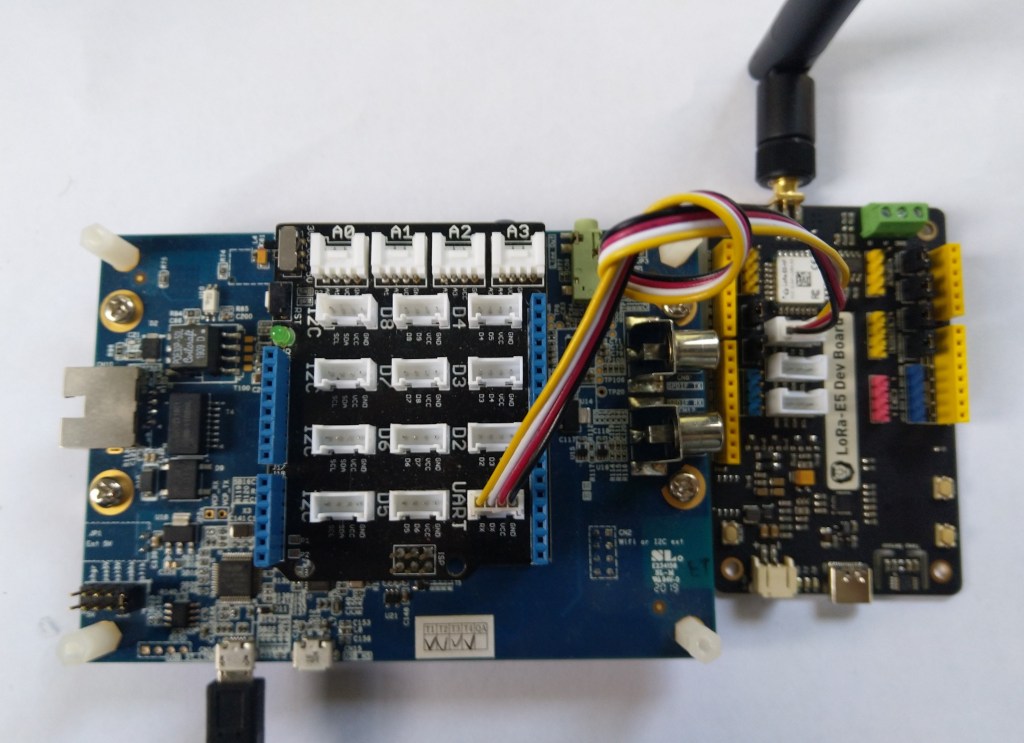

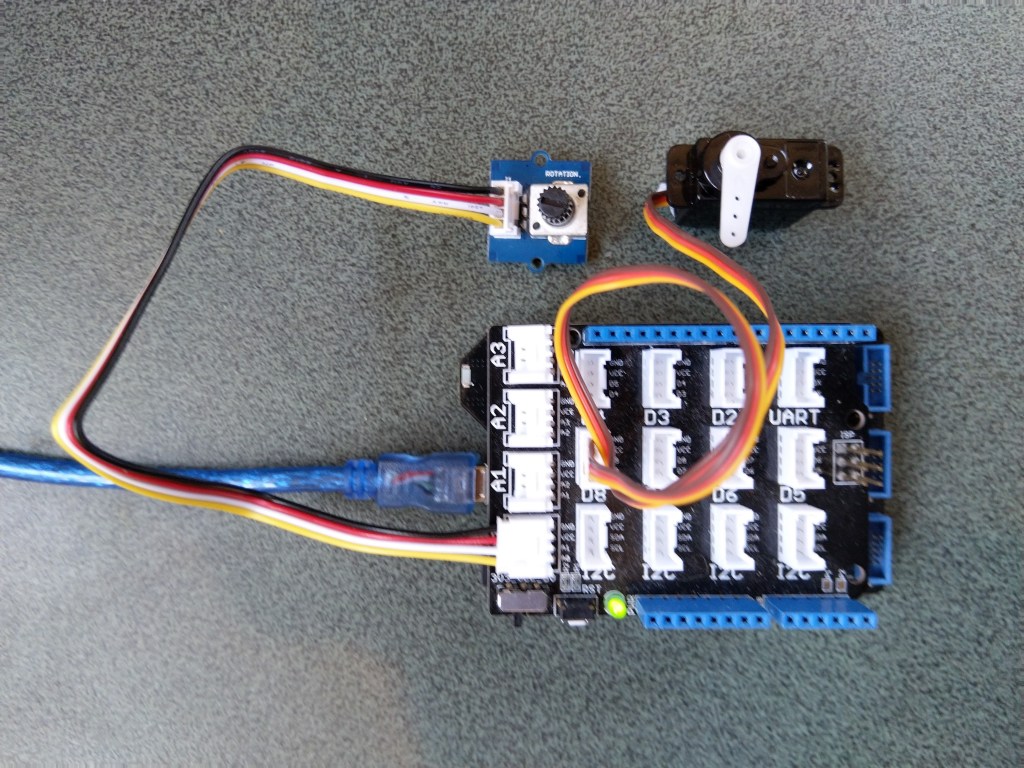

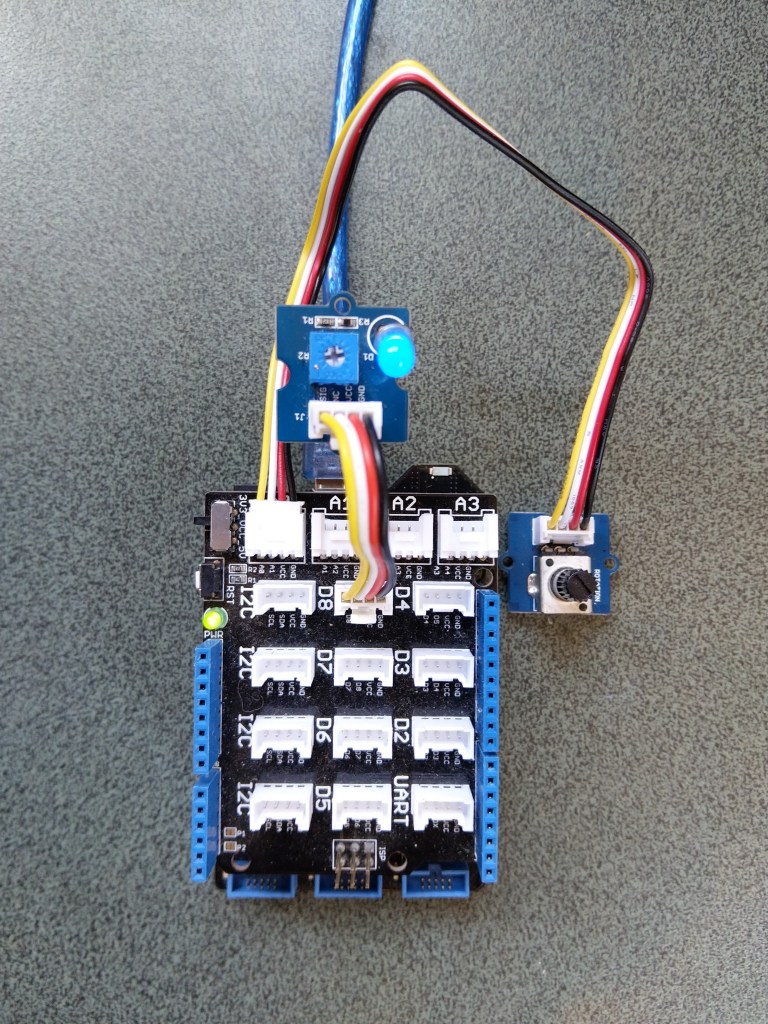

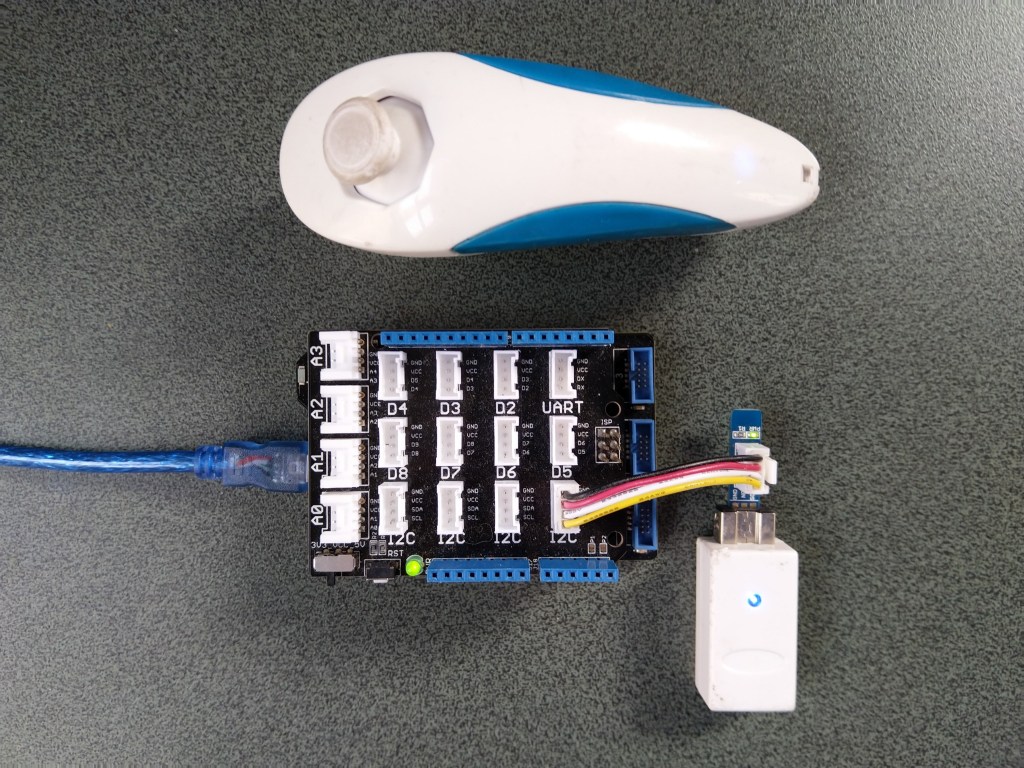

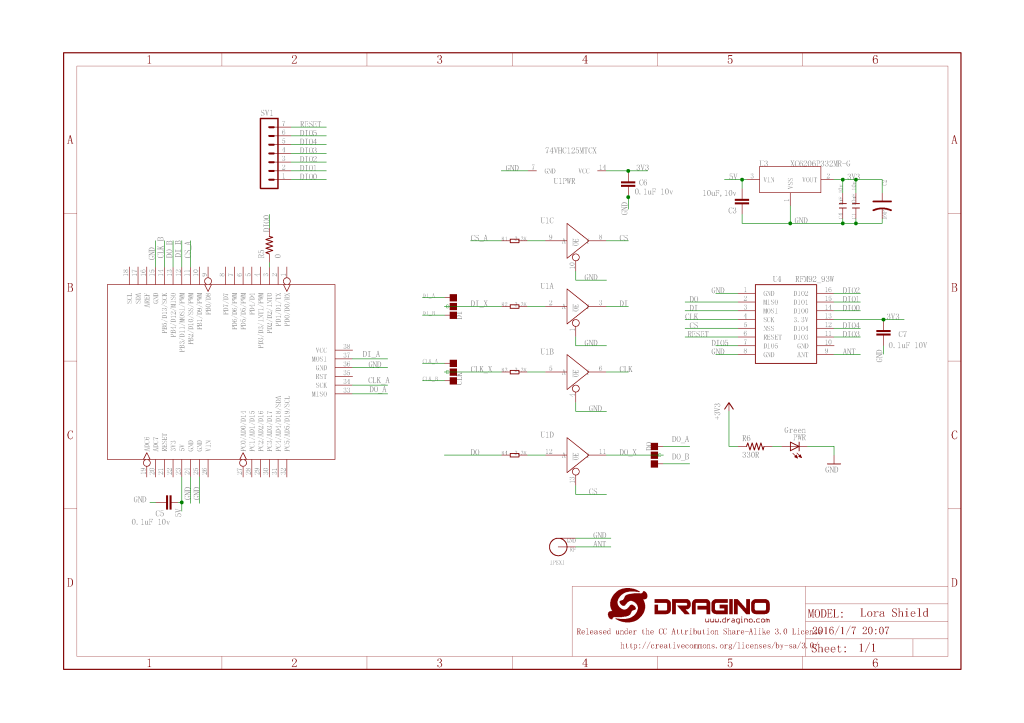

For my updated .NET nanoFramework port I have mainly used a half a dozen Dragino LoRa shields for Arduino and Netduino 3 Wifi devices I had lying around. I have also tested the code with SparkFun LoRa Gateway-1-Channel (ESP32) and ST 32F769IDiscovery devices.

The Dragino shield uses D10 for chip select, D2 for RFM9X DI0 interrupt and D9 for Reset.

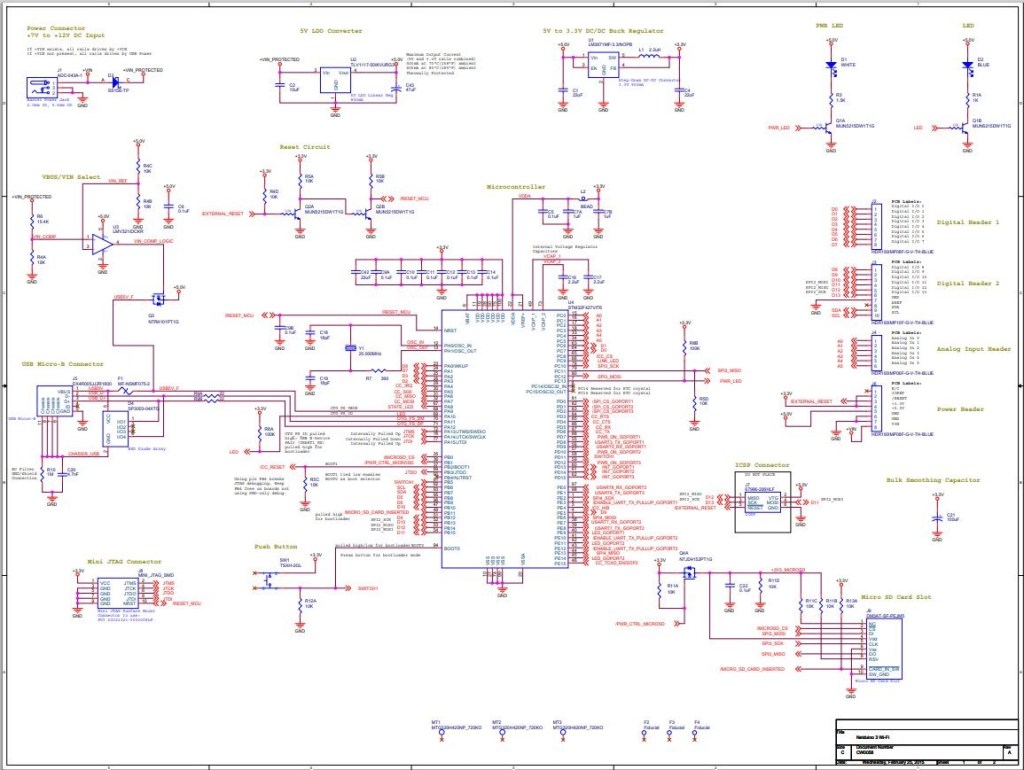

Netduino 3 Wifi pin mapping

- D10->CS->PB10

- D9->RST->E5

ST 32F769IDiscovery pin mapping

D10->CS->PA11

D9->RST->PH6

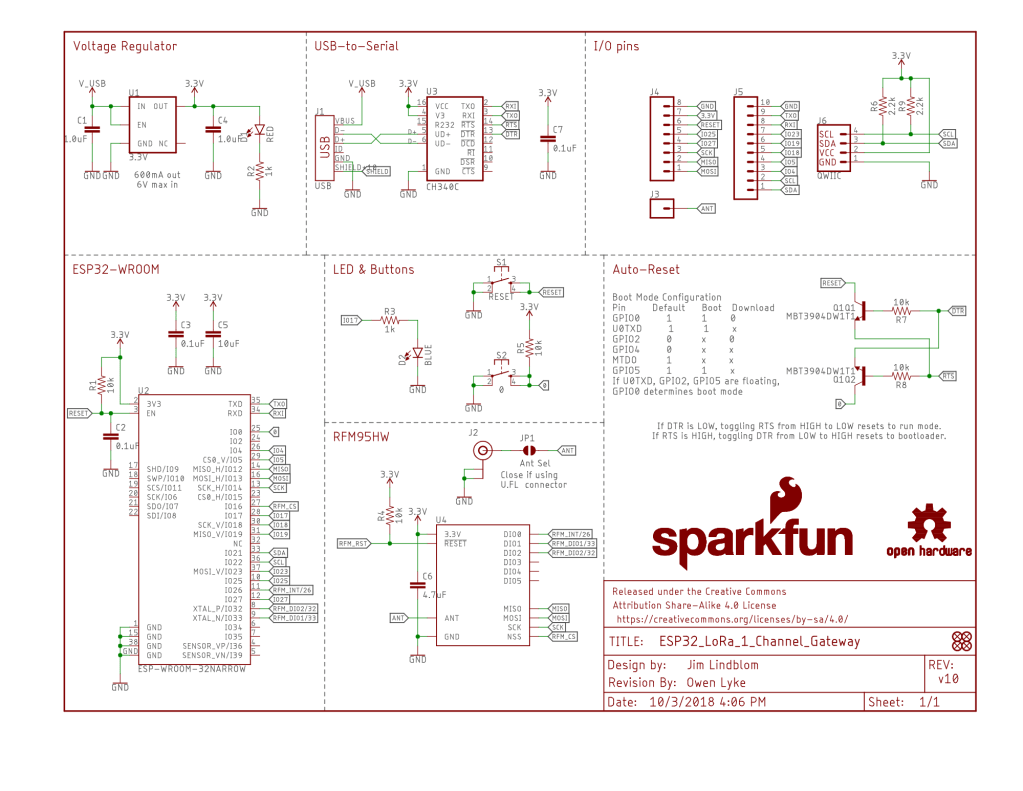

SparkFun LoRa Gateway-1-Channel (ESP32) pin mapping(SX127X reset is not connected)

- CS->PB10

The first step was to confirm I could read a single(ShieldSPI) then scan all the Semtech SX1276 registers with the new nanoFramework System.Device.SPI Nuget (which was”inspired by” .Net Core System.Device.SPI)

namespace devMobile.IoT.SX127x.ShieldSPI

{

using System;

using System.Diagnostics;

using System.Threading;

using System.Device.Gpio;

using System.Device.Spi;

#if ESP32_WROOM_32_LORA_1_CHANNEL

using nanoFramework.Hardware.Esp32;

#endif

public class Program

{

private const byte RegVersion = 0x42;

#if ESP32_WROOM_32_LORA_1_CHANNEL

private const int SpiBusId = 1;

#endif

#if NETDUINO3_WIFI

private const int SpiBusId = 2;

#endif

#if ST_STM32F769I_DISCOVERY

private const int SpiBusId = 2;

#endif

public static void Main()

{

GpioController gpioController = new GpioController();

#if ESP32_WROOM_32_LORA_1_CHANNEL // No reset line for this device as it isn't connected on SX127X

int ledPinNumber = Gpio.IO17;

int chipSelectLine = Gpio.IO16;

#endif

#if NETDUINO3_WIFI

int ledPinNumber = PinNumber('A', 10);

// Arduino D10->PB10

int chipSelectLine = PinNumber('B', 10);

// Arduino D9->PE5

int resetPinNumber = PinNumber('E', 5);

#endif

#if ST_STM32F769I_DISCOVERY

int ledPinNumber = PinNumber('J', 5);

// Arduino D10->PA11

int chipSelectLine = PinNumber('A', 11);

// Arduino D9->PH6

int resetPinNumber = PinNumber('H', 6);

#endif

Debug.WriteLine("devMobile.IoT.SX127x.ShieldSPI starting");

try

{

#if ESP32_WROOM_32_LORA_1_CHANNEL || NETDUINO3_WIFI || ST_STM32F769I_DISCOVERY

// Setup the onboard LED

gpioController.OpenPin(ledPinNumber, PinMode.Output);

#endif

#if NETDUINO3_WIFI || ST_STM32F769I_DISCOVERY

// Setup the reset pin

gpioController.OpenPin(resetPinNumber, PinMode.Output);

gpioController.Write(resetPinNumber, PinValue.High);

#endif

#if ESP32_WROOM_32_LORA_1_CHANNEL

Configuration.SetPinFunction(Gpio.IO12, DeviceFunction.SPI1_MISO);

Configuration.SetPinFunction(Gpio.IO13, DeviceFunction.SPI1_MOSI);

Configuration.SetPinFunction(Gpio.IO14, DeviceFunction.SPI1_CLOCK);

#endif

var settings = new SpiConnectionSettings(SpiBusId, chipSelectLine)

{

ClockFrequency = 1000000,

Mode = SpiMode.Mode0,// From SemTech docs pg 80 CPOL=0, CPHA=0

SharingMode = SpiSharingMode.Shared,

};

using (SpiDevice device = SpiDevice.Create(settings))

{

Thread.Sleep(500);

while (true)

{

byte[] writeBuffer = new byte[] { RegVersion, 0x0 };

byte[] readBuffer = new byte[writeBuffer.Length];

device.TransferFullDuplex(writeBuffer, readBuffer);

Debug.WriteLine(String.Format("Register 0x{0:x2} - Value 0X{1:x2}", RegVersion, readBuffer[1]));

#if ESP32_WROOM_32_LORA_1_CHANNEL || NETDUINO3_WIFI || ST_STM32F769I_DISCOVERY

if ( gpioController.Read(ledPinNumber) == PinValue.High)

{

gpioController.Write(ledPinNumber, PinValue.Low);

}

else

{

gpioController.Write(ledPinNumber, PinValue.High);

}

#endif

Thread.Sleep(10000);

}

}

}

catch (Exception ex)

{

Debug.WriteLine(ex.Message);

}

}

#if NETDUINO3_WIFI || ST_STM32F769I_DISCOVERY

static int PinNumber(char port, byte pin)

{

if (port < 'A' || port > 'J')

throw new ArgumentException();

return ((port - 'A') * 16) + pin;

}

#endif

}

}

namespace devMobile.IoT.SX127x.RegisterScan

{

using System;

using System.Diagnostics;

using System.Threading;

using System.Device.Gpio;

using System.Device.Spi;

#if ESP32_WROOM_32_LORA_1_CHANNEL

using nanoFramework.Hardware.Esp32;

#endif

public sealed class SX127XDevice

{

private readonly SpiDevice SX127XTransceiver;

public SX127XDevice(int busId, int chipSelectLine)

{

var settings = new SpiConnectionSettings(busId, chipSelectLine)

{

ClockFrequency = 1000000,

Mode = SpiMode.Mode0,// From SemTech docs pg 80 CPOL=0, CPHA=0

SharingMode = SpiSharingMode.Shared

};

SX127XTransceiver = new SpiDevice(settings);

}

public SX127XDevice(int busId, int chipSelectLine, int resetPin)

{

var settings = new SpiConnectionSettings(busId, chipSelectLine)

{

ClockFrequency = 1000000,

Mode = SpiMode.Mode0,// From SemTech docs pg 80 CPOL=0, CPHA=0

SharingMode = SpiSharingMode.Shared

};

SX127XTransceiver = new SpiDevice(settings);

// Factory reset pin configuration

GpioController gpioController = new GpioController();

gpioController.OpenPin(resetPin, PinMode.Output);

gpioController.Write(resetPin, PinValue.Low);

Thread.Sleep(20);

gpioController.Write(resetPin, PinValue.High);

Thread.Sleep(20);

}

public Byte RegisterReadByte(byte registerAddress)

{

byte[] writeBuffer = new byte[] { registerAddress, 0x0 };

byte[] readBuffer = new byte[writeBuffer.Length];

SX127XTransceiver.TransferFullDuplex(writeBuffer, readBuffer);

return readBuffer[1];

}

}

public class Program

{

#if ESP32_WROOM_32_LORA_1_CHANNEL

private const int SpiBusId = 1;

#endif

#if NETDUINO3_WIFI

private const int SpiBusId = 2;

#endif

#if ST_STM32F769I_DISCOVERY

private const int SpiBusId = 2;

#endif

public static void Main()

{

#if ESP32_WROOM_32_LORA_1_CHANNEL

int chipSelectLine = Gpio.IO16;

#endif

#if NETDUINO3_WIFI

// Arduino D10->PB10

int chipSelectLine = PinNumber('B', 10);

// Arduino D9->PE5

int resetPinNumber = PinNumber('E', 5);

#endif

#if ST_STM32F769I_DISCOVERY

// Arduino D10->PA11

int chipSelectLine = PinNumber('A', 11);

// Arduino D9->PH6

int resetPinNumber = PinNumber('H', 6);

#endif

Debug.WriteLine("devMobile.IoT.SX127x.RegisterScan starting");

try

{

#if NETDUINO3_WIFI || ST_STM32F769I_DISCOVERY

SX127XDevice sx127XDevice = new SX127XDevice(SpiBusId, chipSelectLine, resetPinNumber);

#endif

#if ESP32_WROOM_32_LORA_1_CHANNEL

Configuration.SetPinFunction(Gpio.IO12, DeviceFunction.SPI1_MISO);

Configuration.SetPinFunction(Gpio.IO13, DeviceFunction.SPI1_MOSI);

Configuration.SetPinFunction(Gpio.IO14, DeviceFunction.SPI1_CLOCK);

SX127XDevice sx127XDevice = new SX127XDevice(SpiBusId, chipSelectLine);

#endif

Thread.Sleep(500);

while (true)

{

for (byte registerIndex = 0; registerIndex <= 0x42; registerIndex++)

{

byte registerValue = sx127XDevice.RegisterReadByte(registerIndex);

Debug.WriteLine($"Register 0x{registerIndex:x2} - Value 0X{registerValue:x2}");

}

Debug.WriteLine("");

Thread.Sleep(10000);

}

}

catch (Exception ex)

{

Debug.WriteLine(ex.Message);

}

}

#if NETDUINO3_WIFI || ST_STM32F769I_DISCOVERY

static int PinNumber(char port, byte pin)

{

if (port < 'A' || port > 'J')

throw new ArgumentException();

return ((port - 'A') * 16) + pin;

}

#endif

}

}

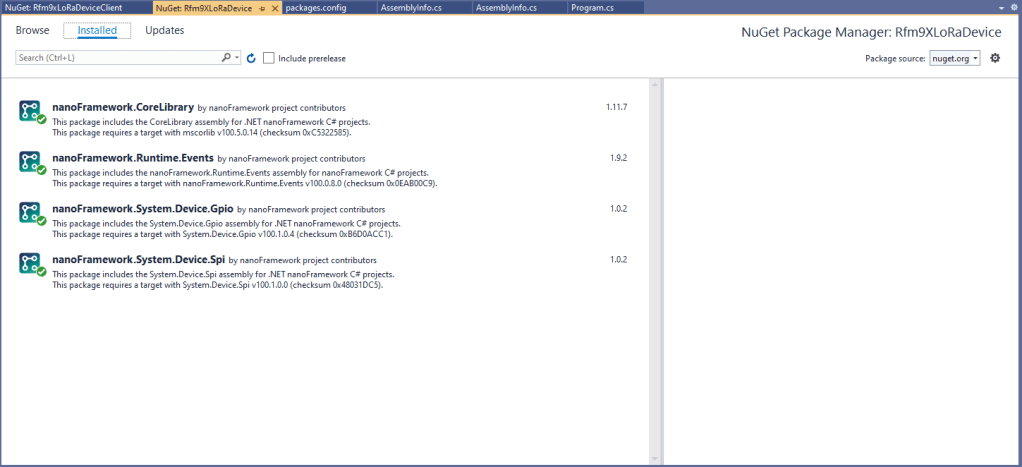

There is some SparkFun LoRa Gateway-1-Channel (ESP32) specific configuration to map the Serial Peripheral Interface(SPI) pins and an additional NuGet for ESP32 has to be added. For the initial versions I have not used more advanced .NET nanoFramework functionality like SpanByte.