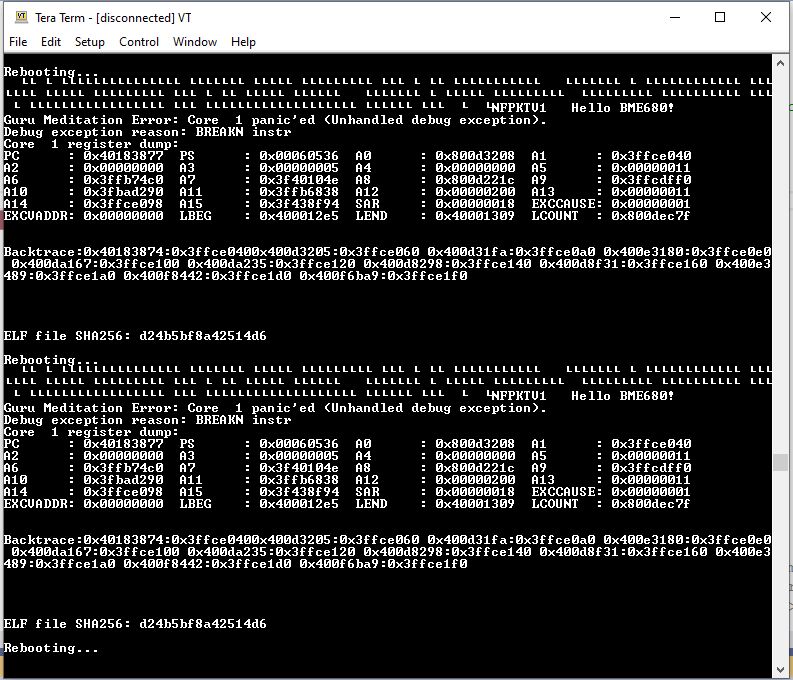

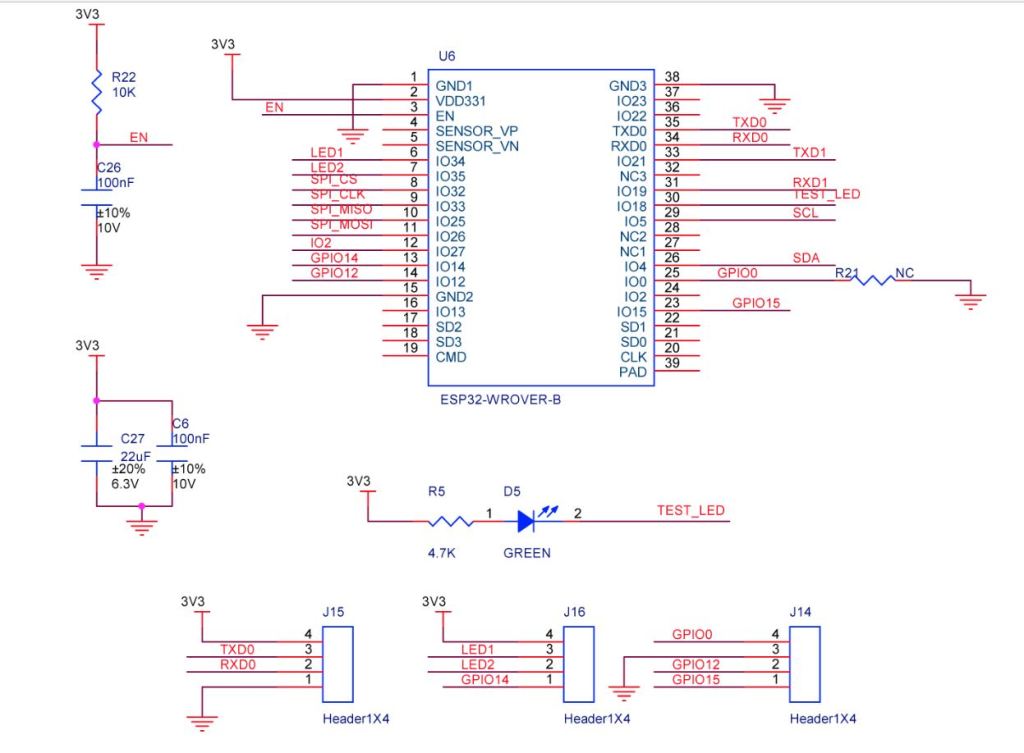

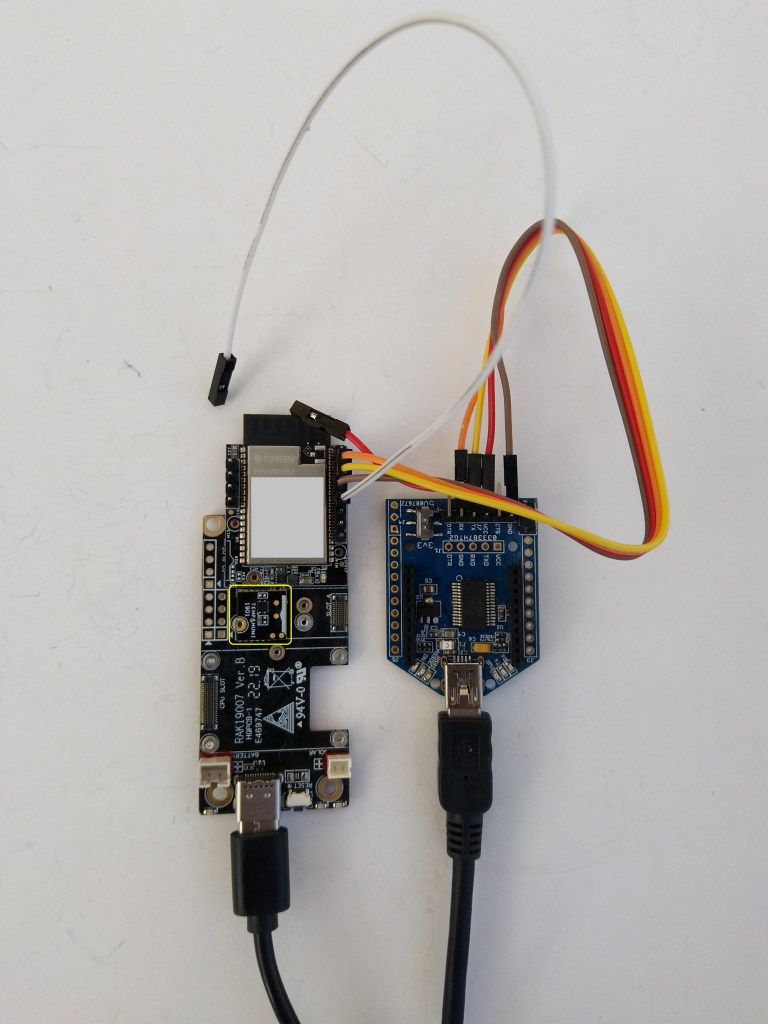

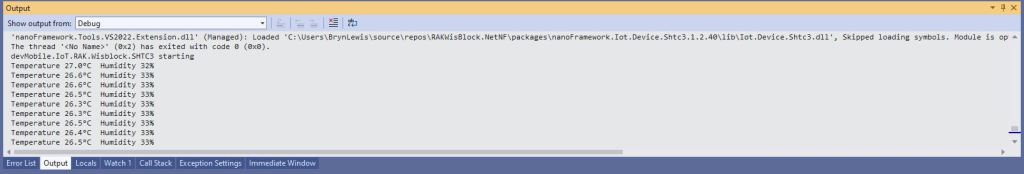

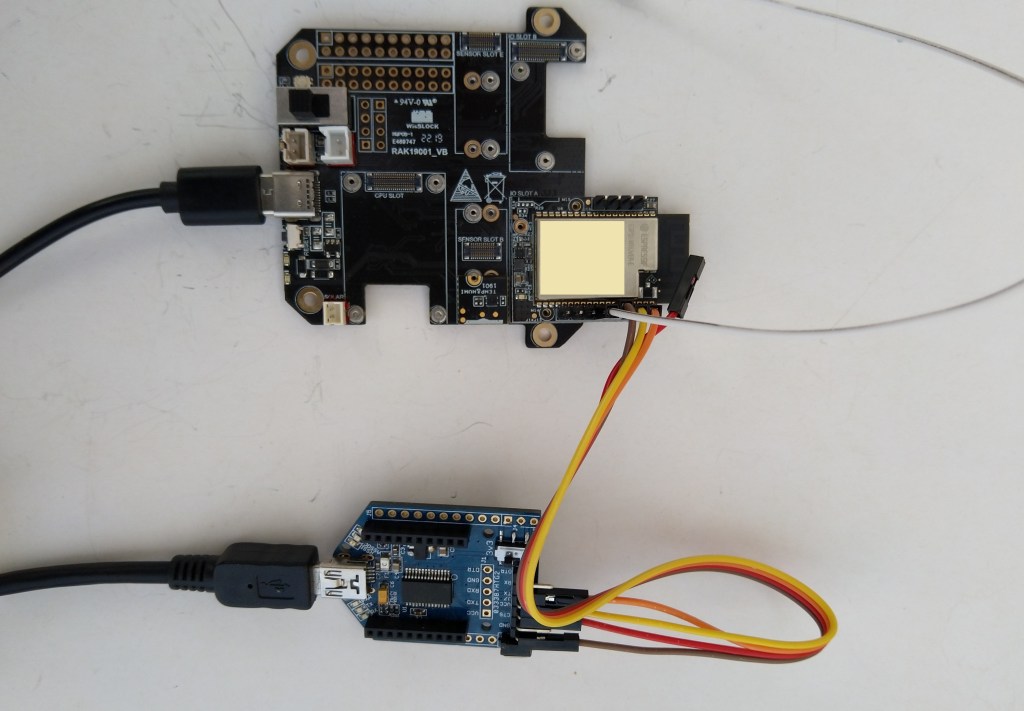

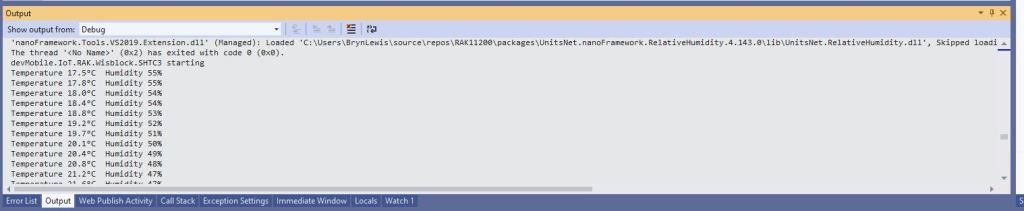

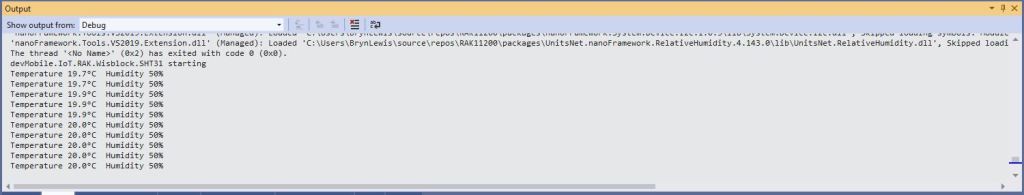

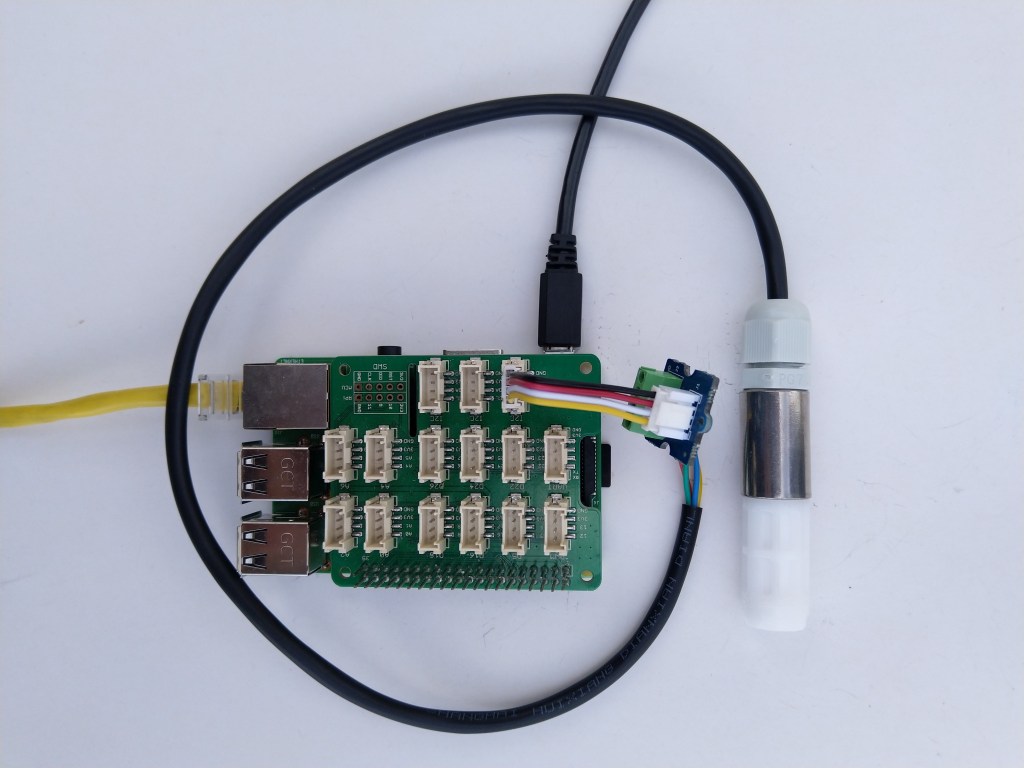

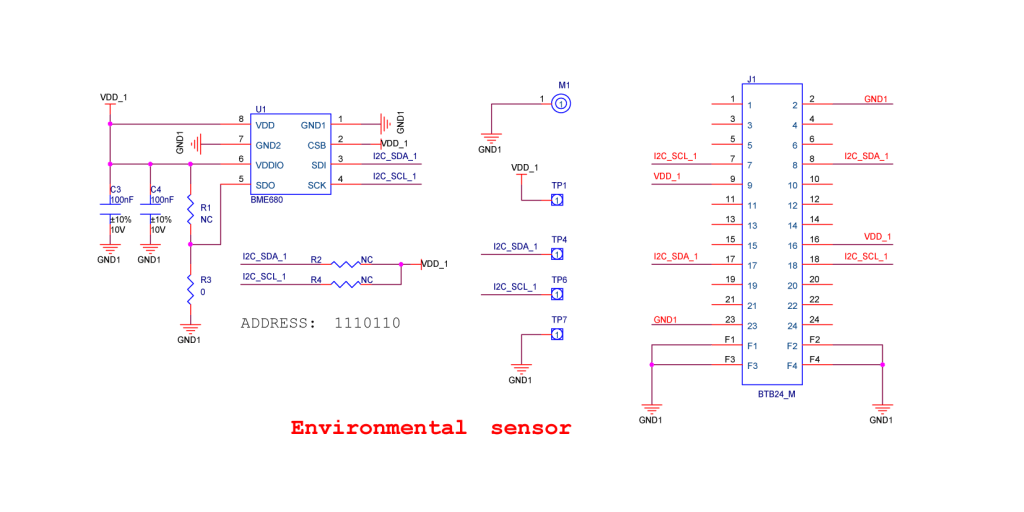

Reading the RAK1906 WisBlock Environment Sensor/BME680 GasResistance was failing randomly so I decided to dig a bit deeper. I checked the termination resistors, made sure the sensor was firmly seated on the RAK5005, and tried another Inter-Integrated Circuit(I²C) device on the same physical port.

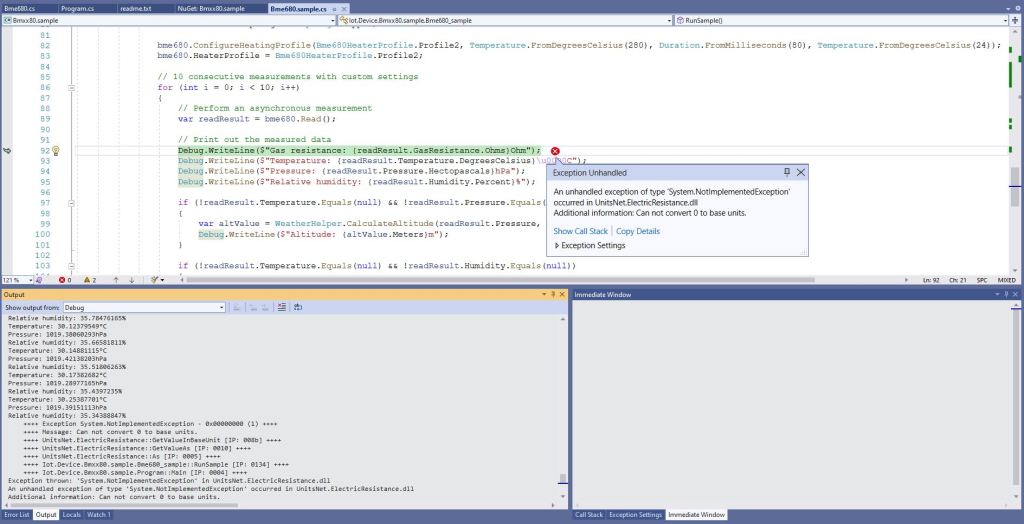

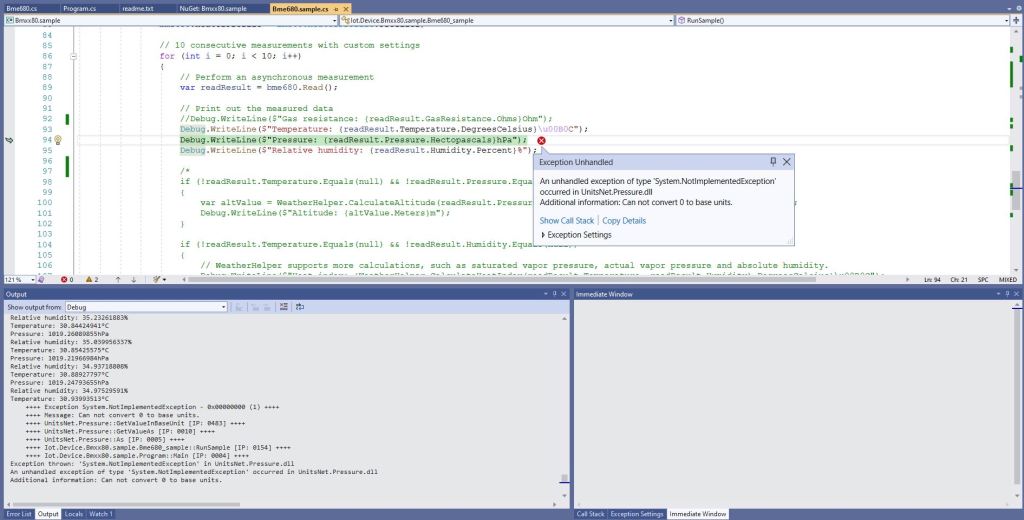

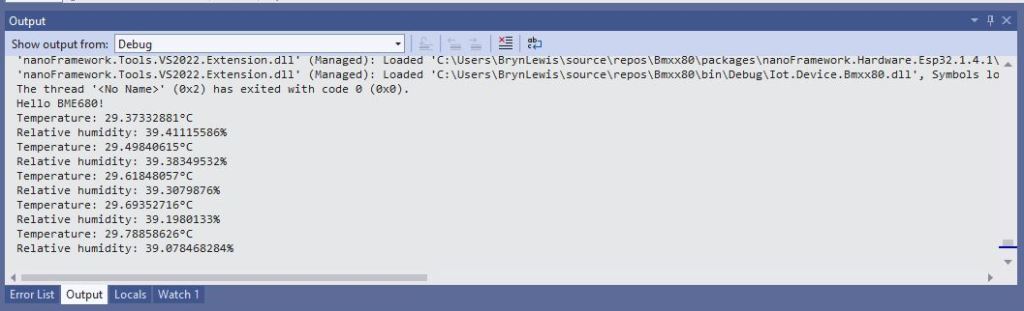

I then used Visual Studio 2022 Debugger to “single step” further into the BME680 code and the first thing that looked a bit odd was the TryReadTemperatureCore, TryReadPressureCore, TryReadHumidityCore and TryReadGasResistanceCore return values were ignored.

/// <summary>

/// Performs a synchronous reading.

/// </summary>

/// <returns><see cref="Bme680ReadResult"/></returns>

public Bme680ReadResult Read()

{

SetPowerMode(Bme680PowerMode.Forced);

Thread.Sleep((int)GetMeasurementDuration(HeaterProfile).Milliseconds);

TryReadTemperatureCore(out Temperature temperature);

TryReadPressureCore(out Pressure pressure, skipTempFineRead: true);

TryReadHumidityCore(out RelativeHumidity humidity, skipTempFineRead: true);

TryReadGasResistanceCore(out ElectricResistance gasResistance);

return new Bme680ReadResult(temperature, pressure, humidity, gasResistance);

}

I then single stepped into the TryReadTemperatureCore which was returning a boolean indicating whether the read was success.

private bool TryReadTemperatureCore(out Temperature temperature)

{

if (TemperatureSampling == Sampling.Skipped)

{

temperature = default;

return false;

}

var temp = (int)Read24BitsFromRegister((byte)Bme680Register.TEMPDATA, Endianness.BigEndian);

temperature = CompensateTemperature(temp >> 4);

return true;

}

This library was based on the dotnet/iot Bmxx80 code, it looked similar, but I missed an important detail lots more ?’s…

Console.WriteLine("Hello BME680!");

// The I2C bus ID on the Raspberry Pi 3.

const int busId = 1;

// set this to the current sea level pressure in the area for correct altitude readings

Pressure defaultSeaLevelPressure = WeatherHelper.MeanSeaLevel;

I2cConnectionSettings i2cSettings = new(busId, Bme680.DefaultI2cAddress);

I2cDevice i2cDevice = I2cDevice.Create(i2cSettings);

using Bme680 bme680 = new Bme680(i2cDevice, Temperature.FromDegreesCelsius(20.0));

while (true)

{

// reset will change settings back to default

bme680.Reset();

// 10 consecutive measurement with default settings

for (var i = 0; i < 10; i++)

{

// Perform a synchronous measurement

var readResult = bme680.Read();

// Print out the measured data

Console.WriteLine($"Gas resistance: {readResult.GasResistance?.Ohms:0.##}Ohm");

Console.WriteLine($"Temperature: {readResult.Temperature?.DegreesCelsius:0.#}\u00B0C");

Console.WriteLine($"Pressure: {readResult.Pressure?.Hectopascals:0.##}hPa");

Console.WriteLine($"Relative humidity: {readResult.Humidity?.Percent:0.#}%");

if (readResult.Temperature.HasValue && readResult.Pressure.HasValue)

{

var altValue = WeatherHelper.CalculateAltitude(readResult.Pressure.Value, defaultSeaLevelPressure, readResult.Temperature.Value);

Console.WriteLine($"Altitude: {altValue.Meters:0.##}m");

}

if (readResult.Temperature.HasValue && readResult.Humidity.HasValue)

{

// WeatherHelper supports more calculations, such as saturated vapor pressure, actual vapor pressure and absolute humidity.

Console.WriteLine($"Heat index: {WeatherHelper.CalculateHeatIndex(readResult.Temperature.Value, readResult.Humidity.Value).DegreesCelsius:0.#}\u00B0C");

Console.WriteLine($"Dew point: {WeatherHelper.CalculateDewPoint(readResult.Temperature.Value, readResult.Humidity.Value).DegreesCelsius:0.#}\u00B0C");

}

// when measuring the gas resistance on each cycle it is important to wait a certain interval

// because a heating plate is activated which will heat up the sensor without sleep, this can

// falsify all readings coming from the sensor

Thread.Sleep(1000);

}

...

}

The Bme680 Read() method checked the TryReadTemperatureCore, TryReadPressureCore, TryReadHumidityCore & TryReadGasResistanceCore return values.

/// <summary>

/// Performs a synchronous reading.

/// </summary>

/// <returns><see cref="Bme680ReadResult"/></returns>

public Bme680ReadResult Read()

{

SetPowerMode(Bme680PowerMode.Forced);

Thread.Sleep((int)GetMeasurementDuration(HeaterProfile).Milliseconds);

var tempSuccess = TryReadTemperatureCore(out var temperature);

var pressSuccess = TryReadPressureCore(out var pressure, skipTempFineRead: true);

var humiditySuccess = TryReadHumidityCore(out var humidity, skipTempFineRead: true);

var gasSuccess = TryReadGasResistanceCore(out var gasResistance);

return new Bme680ReadResult(tempSuccess ? temperature : null, pressSuccess ? pressure : null, humiditySuccess ? humidity : null, gasSuccess ? gasResistance : null);

}

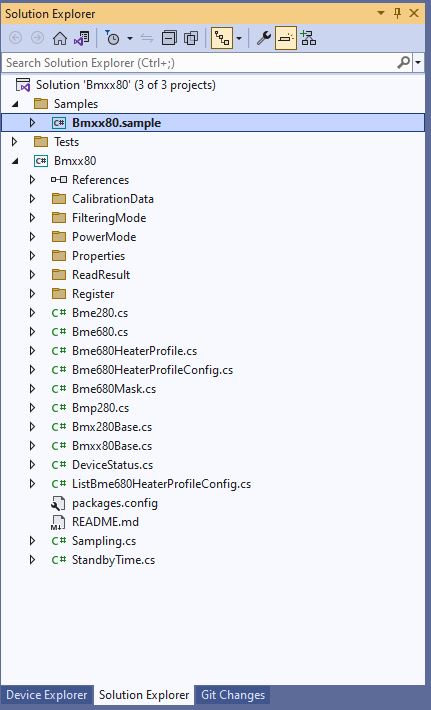

The dotnet/iot Bmxx80 library uses Nullable reference types which are not supported by the nanoFramework(Sept 2022), and this was overlooked when the library was ported.

I have created a Github issue.