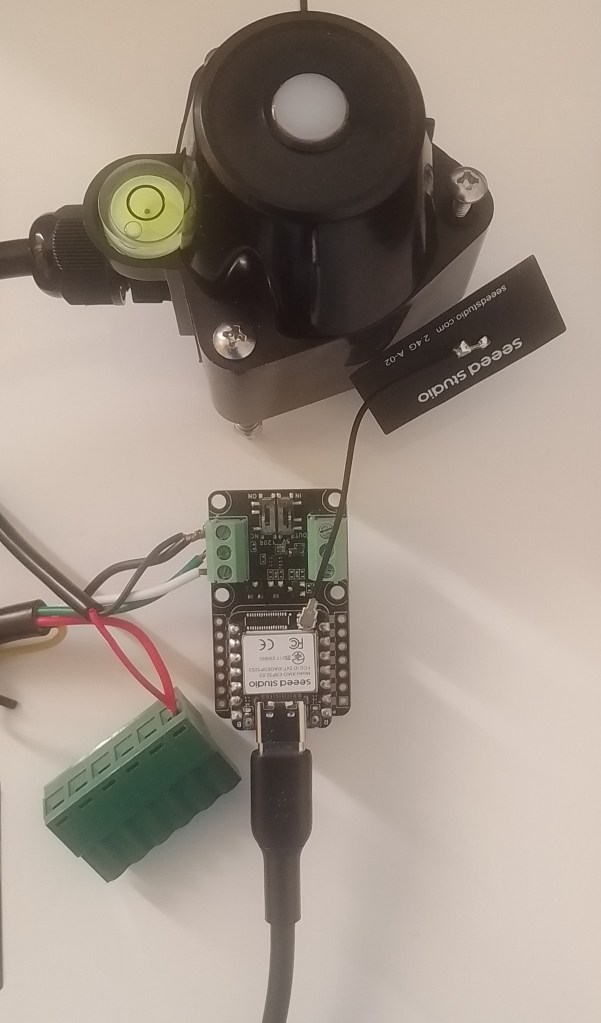

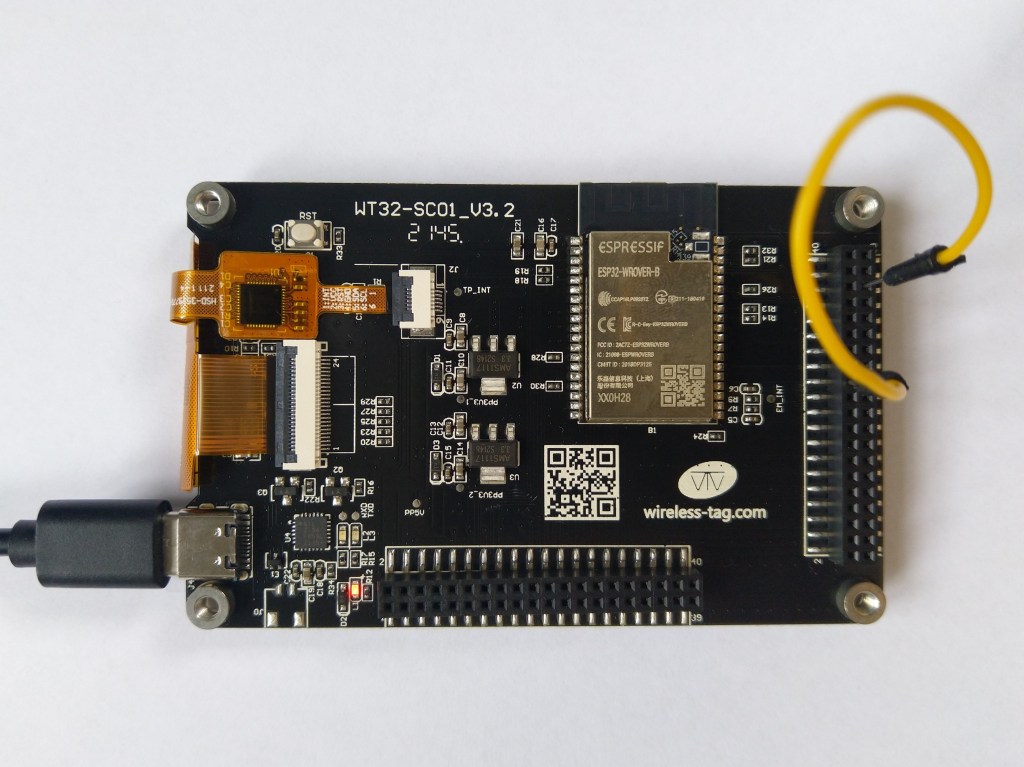

As part of this series of samples comparing Arduino to nanoFramework to .NET IoT Device “Proof of Concept (PoC) applications, several posts use a SenseCap Industrial Light Intensity Sensor (SKU314990739 or SKU 314990740)

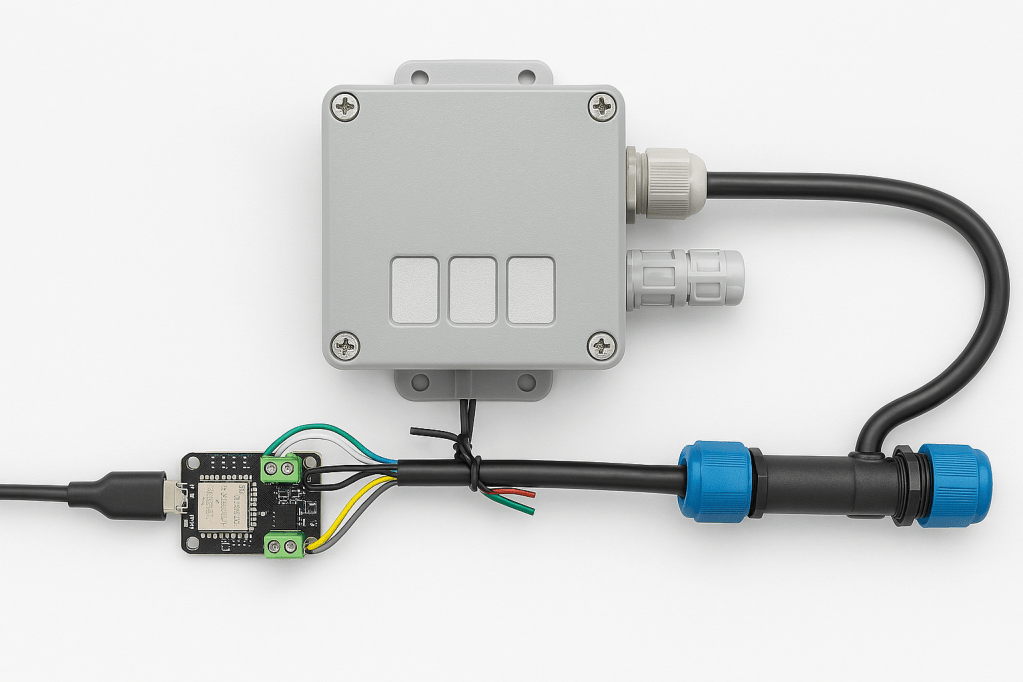

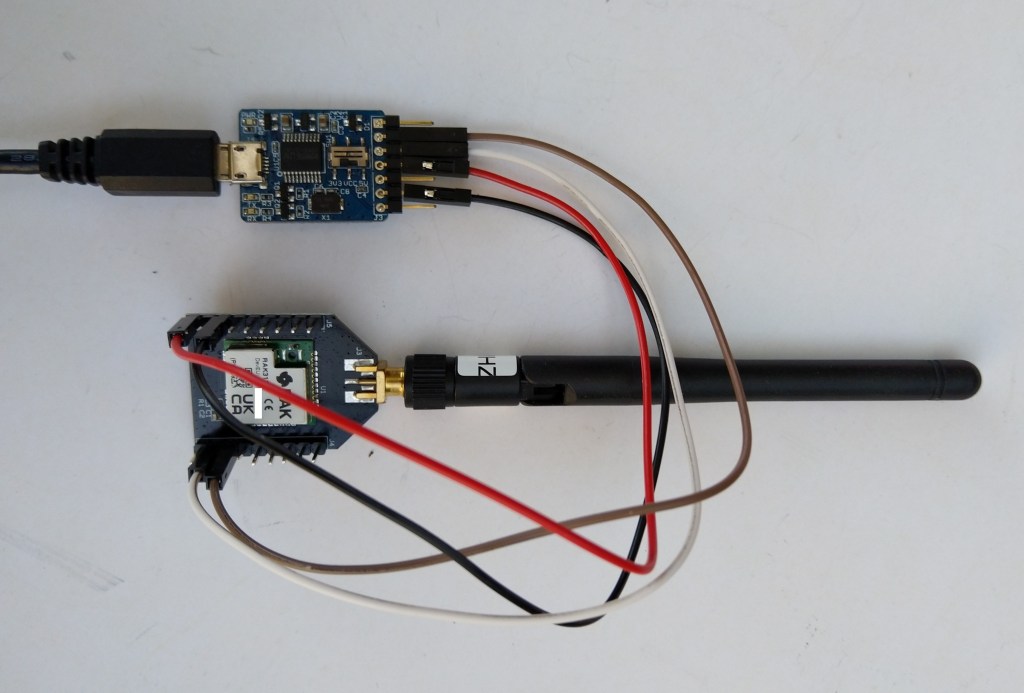

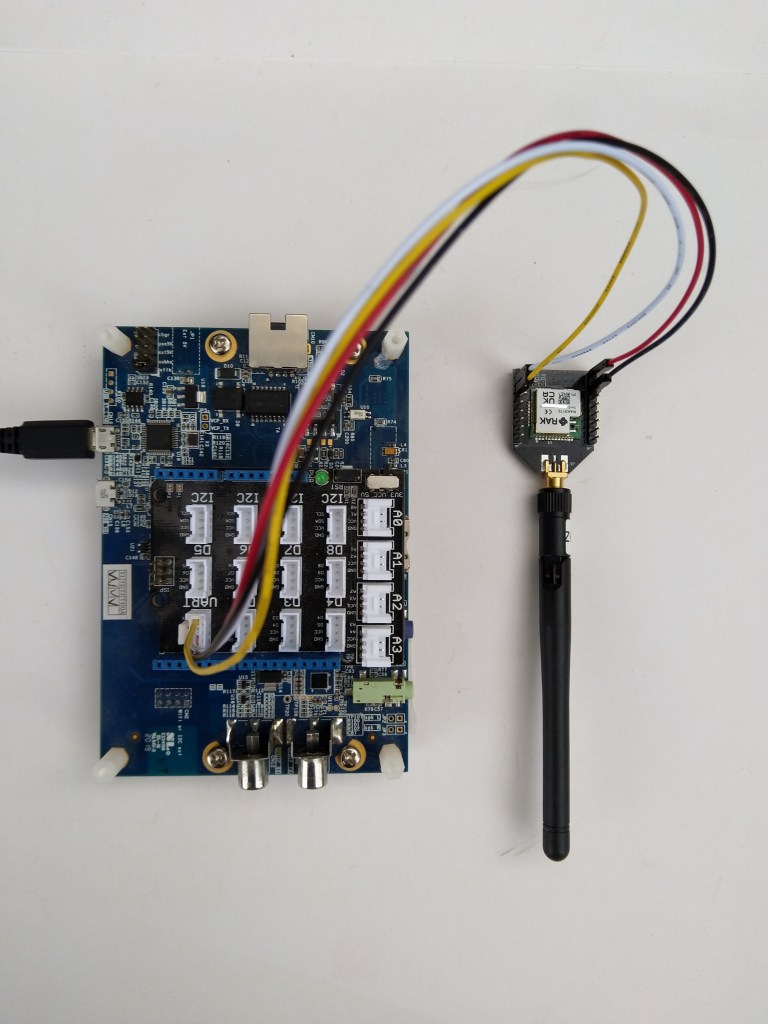

I cut one of the cables of a spare Industrial IP68 Modbus RS485 1-to-4 Splitter/Hub to connect the sensor to the RS485 breakout board.

The sensor has an operating voltage of 3.6-30V but it is connected to the 12V supply pin. Initially, I had the sensor connected to the 5V output of the RS485 Breakout Board for Seeed Studio XIAO (SKU 113991354) so it didn’t work.

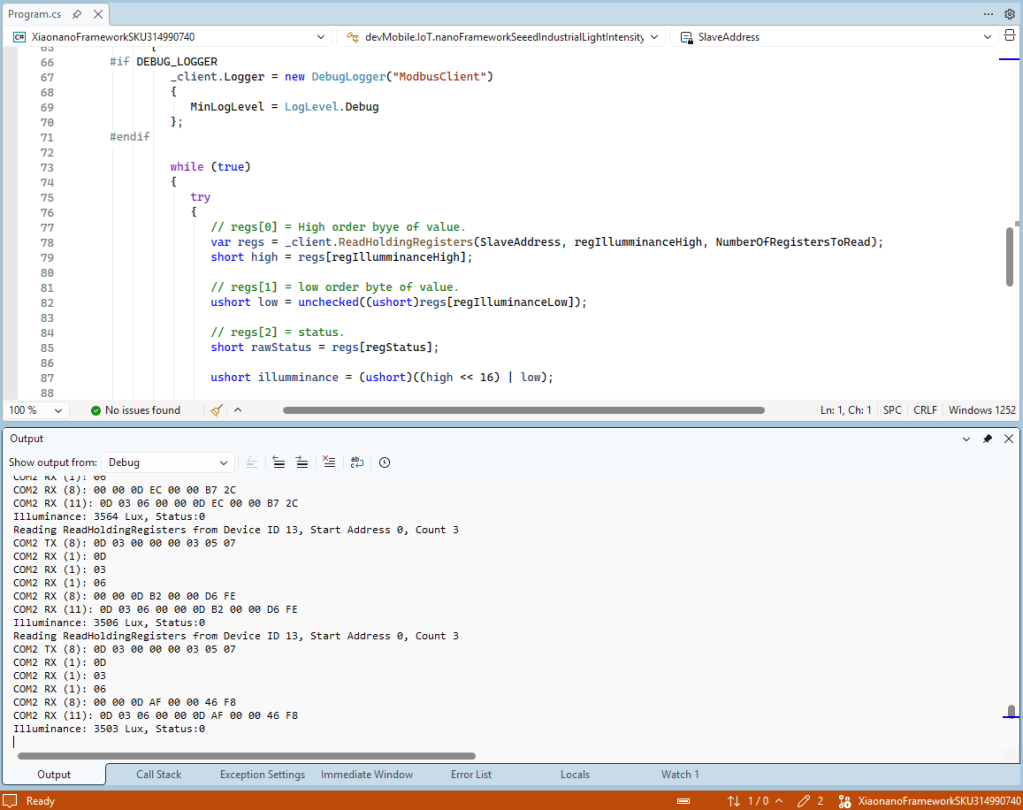

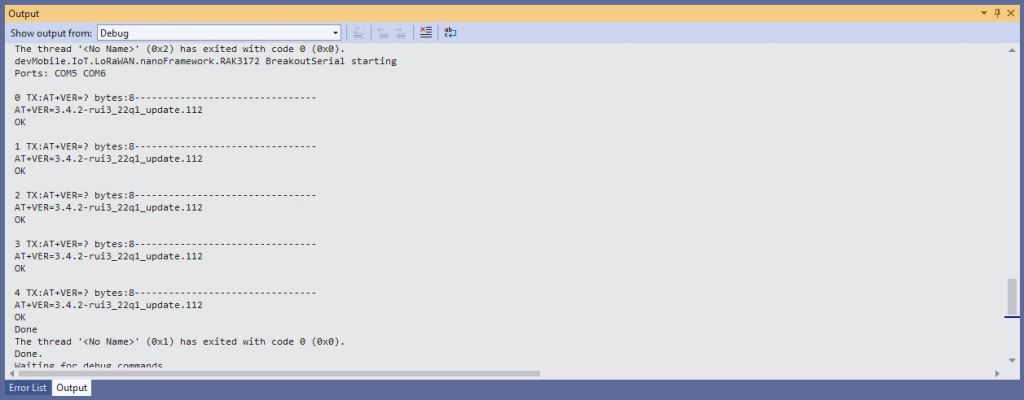

// Modbus Client

using (var _client = new ModbusClient("COM2"))

{

#if DEBUG_LOGGER

_client.Logger = new DebugLogger("ModbusClient")

{

MinLogLevel = LogLevel.Debug

};

#endif

while (true)

{

try

{

// regs[0] = High order byye of value.

var regs = _client.ReadHoldingRegisters(SlaveAddress, regIllumminanceHigh, NumberOfRegistersToRead);

short high = regs[regIllumminanceHigh];

// regs[1] = low order byte of value.

ushort low = unchecked((ushort)regs[regIlluminanceLow]);

// regs[2] = status.

short rawStatus = regs[regStatus];

ushort illumminance = (ushort)((high << 16) | low);

Console.WriteLine($"Illuminance: {illumminance} Lux, Status:{rawStatus}");

}

catch (Exception ex)

{

Console.WriteLine($"Read failed: {ex.Message}");

}

Thread.Sleep(60000);

}

}

For the next version the “status” value will be mapped to an enumeration.