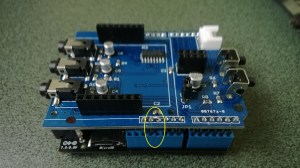

The Netduino 2 Plus AnalogInput has a range of 0V to 3V3. The Non Invasive Current Sensor we are using returns 0-1V AC for 0-30 Amps AC. To measure the sensor’s output waveform the Energy Monitor Shield uses a voltage divider to offset the reference voltage to 3v3/2. To calibrate the sensor we averaged the input voltage and over 100,000 readings.

The initial code looked like this

int value;

int valueSum = 0;

AnalogInput x1 = new AnalogInput(Cpu.AnalogChannel.ANALOG_0);

stopwatch.Start();

for (int i = 0; i < SampleCount; i++)

{

value = x1.ReadRaw();

valueSum = valueSum + value;

}

stopwatch.Stop();

Duration = 2272 mSec 44014/sec

Duration = 2273 mSec 43994/sec

Duration = 2272 mSec 44014/sec

Duration = 2272 mSec 44014/sec

Duration = 2272 mSec 44014/sec

Duration = 2272 mSec 44014/sec

Duration = 2272 mSec 44014/sec

Duration = 2272 mSec 44014/sec

Duration = 2272 mSec 44014/sec

Duration = 2272 mSec 44014/sec

I then modified the code to not use a temporary variable

int valueSum = 0;

AnalogInput x1 = new AnalogInput(Cpu.AnalogChannel.ANALOG_0);

stopwatch.Start();

for (int i = 0; i < SampleCount; i++)

{

valueSum = valueSum + x1.ReadRaw();

}

stopwatch.Stop();

Duration = 2181 mSec 45829/sec

Duration = 2182 mSec 45829/sec

Duration = 2181 mSec 45829/sec

Duration = 2181 mSec 45829/sec

Duration = 2181 mSec 45829/sec

Duration = 2181 mSec 45829/sec

Duration = 2181 mSec 45829/sec

Duration = 2181 mSec 45829/sec

Duration = 2181 mSec 45829/sec

Duration = 2181 mSec 45829/sec

The code without the temporary variable was slightly faster.