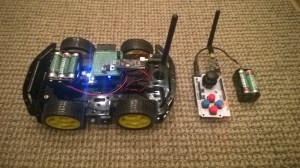

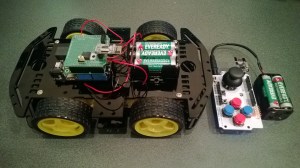

At EV Camp in June 2014 I talked about real-time telemetry for the electric carts. This is a demo of how this could be done using a couple of Netduinos, nRF24L01 modules and some other hardware

Bill of materials (Prices as at July 2014)

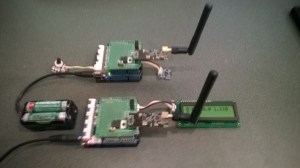

- 2 x Netduino Plus 2 USD60,NZD108 or Netduino 2 USD33,NZD60

- 2 x Embedded Coolness nRF24L01shields V1.1b + high power modules AUD17.85

- 2 x Grove Base Shields V2 USD8.90

- 1 x Grove ADX345 Accelerometer USD9.90

- 1 x Grove Rotary Angle Sensor USD2.90

- 1 x Grove 16×2 LCD USD13.90 (Using earlier serial display in pictures)

The mobile device configures the Gralin nRF24L01 library, initialises the Love Electronics ADXL345 Accelerometer library, and creates two timers, one for the throttle position the other for the accelerometer.

_module.OnTransmitFailed += OnSendFailure; _module.OnTransmitSuccess += OnSendSuccess; _module.Initialize(SPI.SPI_module.SPI1, Pins.GPIO_PIN_D7, Pins.GPIO_PIN_D3, Pins.GPIO_PIN_D2); _module.Configure(myAddress, channel); _module.Enable(); accel.EnsureConnected(); accel.Range = 2; accel.FullResolution = true; accel.EnableMeasurements(); accel.SetDataRate(0x0F); Timer throttlePositionUpdates = new Timer(throttleTimerProc, null, 500, 500); Timer accelerometerUpdates = new Timer(AccelerometerTimerProc, null, 500, 500); Thread.Sleep( Timeout.Infinite ) ;

The Accelerometer timer reads the x, y & z accelerations then sends the data as an ASCII string (rather than Unicode) to save space (maximum message length is 32 bytes)

private void AccelerometerTimerProc(object state)

{

accel.ReadAllAxis();

Debug.Print("A- X = " + accel.ScaledXAxisG.ToString("F2") + " Y = " + accel.ScaledYAxisG.ToString("F2") + " Z = " + accel.ScaledZAxisG.ToString("F2"));

_module.SendTo(baseStationAddress, Encoding.UTF8.GetBytes("A " + accel.ScaledXAxisG.ToString("F1") + " " + accel.ScaledYAxisG.ToString("F1") + " " + accel.ScaledZAxisG.ToString("F1")));

}

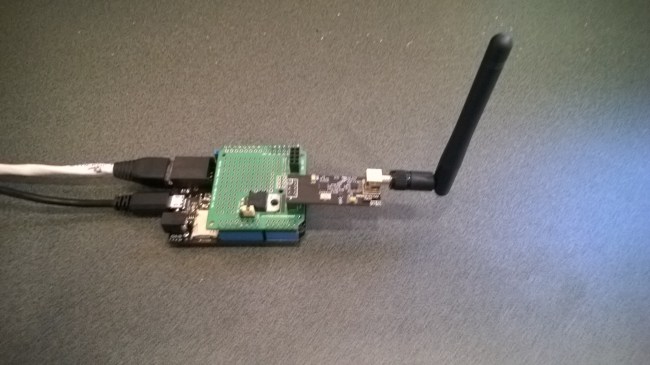

The base station works in a similar way, configuring the nRF24L01 library then displaying the received messages on the LCD Display.