One of CodeClub’s sponsors is Orion Health so I had been looking for some reasonably priced sensors for health focused projects. We already use the SeeedStudio Heart rate sensor for one of our projects so I ordered a Grove EMG Detector for evaluation.

The EMG detector outputs a single analog signal which we connected to analog input 0. For the proof of concept we averaged for 500 samples to determine the steady state offset.

for (int sampleCounter = 0; sampleCounter < calibrationSampleCount; sampleCounter++)

{

double value = emg.Read();

sampleSum += value;

}

offset = sampleSum / calibrationSampleCount ;

We then read the analog input applied the offset and displayed the magnitude of the signal on a Seeedstudio LED bar using code written by Famoury Toure

while(true)

{

double value = emg.Read() - offset;

if (value < valueMinimum) { valueMinimum = value; } if (value > valueMaximum)

{

valueMaximum = value;

}

range = valueMaximum - valueMinimum;

if (value < 0)

{

value = value / valueMaximum * 10.0;

}

else

{

value = value / valueMinimum * 10.0;

}

Debug.Print("Val " + value.ToString("F3") + " Max " + valueMaximum.ToString("F3") + " Min " +valueMinimum.ToString("F3"));

int bar = 1;

value = 10.0 - value;

bar = bar << (int)value ;

ledBar.setLED((uint)bar);

Thread.Sleep(100);

}

}

Bill of Materials (Prices as at October 2014)

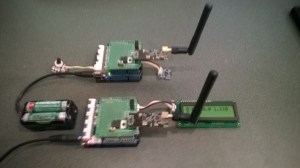

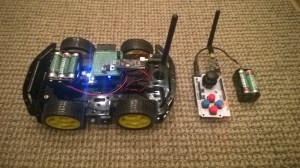

- 2 x Netduino Plus 2 USD60,NZD108 or Netduino 2 USD33,NZD60

- 1 x Grove Base Shield V2 USD8.90

- 1 x Grove LED bar USD3.90

- 1 x Grove EMG Detector USD48

The proof of concept worked surprisingly well, the LED illuminated on the LED bar appeared to move in response to arm movements and when I clenched my fist.