A telemetry system could be used to monitor the progress of your electric vehicle and provide feedback to the team & driver about how efficiently/fast it is being driven. As part of a telemetry system lateral, longitudinal, and vertical acceleration could be monitored using a cheap ADXL345 mems accelerometer

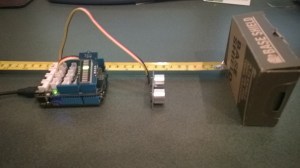

Bill of Materials for my engineering proof of concept (Prices as at May 2015)

- Netduino Plus 2 USD59.95 NZD108.25 (could use a Netduino 2 USD32.95 NZD59.63)

- Grove Base Shield V2 USD8.90

- Grove 3 Axis Accelerometer +-16G USD9.90

- 3 x Grove Led Bar USD3.90

- 4 x Grove 5CM cables USD1.90

The sample code reads the acceleration data from the ADXL345 using a driver originally created by Love Electronics. It then displays the magnitude of the scaled acceleration on 3 x LED Bars using code written by Famoury Toure

OutputPort Xcin = new OutputPort(Pins.GPIO_PIN_D0, false);

OutputPort Xdin = new OutputPort(Pins.GPIO_PIN_D1, false);

OutputPort Ycin = new OutputPort(Pins.GPIO_PIN_D3, false);

OutputPort Ydin = new OutputPort(Pins.GPIO_PIN_D4, false);

OutputPort Zcin = new OutputPort(Pins.GPIO_PIN_D5, false);

OutputPort Zdin = new OutputPort(Pins.GPIO_PIN_D6, false);

GroveLedBarGraph Xbar = new GroveLedBarGraph(Xcin, Xdin);

GroveLedBarGraph Ybar = new GroveLedBarGraph(Ycin, Ydin);

GroveLedBarGraph Zbar = new GroveLedBarGraph(Zcin, Zdin);

using (OutputPort i2cPort = new OutputPort(Pins.GPIO_PIN_SDA, true))

{

i2cPort.Write(false);

}

ADXL345 accel = new ADXL345(0x53);

accel.EnsureConnected();

accel.Range = 2;

accel.FullResolution = true;

accel.EnableMeasurements();

accel.SetDataRate(0x0F);

while (true)

{

accel.ReadAllAxis();

uint xValue = (uint)(((accel.ScaledXAxisG / 1.0 ) + 1.0) * 5.0) ;

uint xbar = 1;

xbar = xbar << (int)xValue;

Xbar.setLED(xbar);

uint yValue = (uint)(((accel.ScaledYAxisG / 1.0) + 1.0) * 5.0);

uint ybar = 1;

ybar = ybar << (int)yValue;

Ybar.setLED(ybar);

uint zValue = (uint)((-(accel.ScaledZAxisG / 1.0) + 2.0) * 5.0);

uint zbar = 1;

zbar = zbar << (int)zValue;

Zbar.setLED(zbar);

Thread.Sleep(20);

}

}