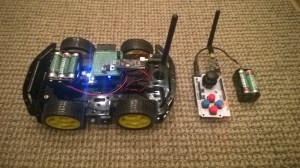

I finally had some time to finish off the 4WD robot I first blogged about in February this year.

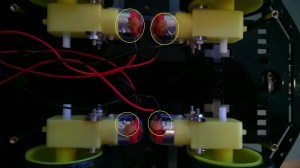

When I fired up the robot the nrf24L01 module on the embedded coolness shield was having some problems with electrical noise from the motors. This noise was causing the wireless module to report errors then stop working. So, based on this article by Pololu I added some noise suppression capacitors. There are two 0.1uF capacitors per motor and they connect the power supply pins to the metal casing of the motor. I have also twisted the motor supply wires and added some capacitors to the motor shield.

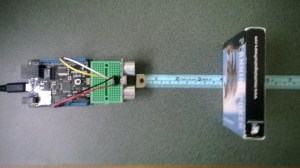

The Elecfreaks Joystick has to be modified to work with a Netduino. The remote control uses the initial position of the joystick for a calibration offset then sends 4 byte commands to the robot every 250mSec. The first two bytes are the motor directions and the last two are the motor speeds.

_module.OnDataReceived += OnReceive; _module.OnTransmitFailed += OnSendFailure; _module.OnTransmitSuccess += OnSendSuccess; _module.Initialize(SPI.SPI_module.SPI1, Pins.GPIO_PIN_D10, Pins.GPIO_PIN_D9, Pins.GPIO_PIN_D1); _module.Configure(_ControllerAddress, channel); _module.Enable(); xOffset = xAxis.Read(); yOffset = yAxis.Read(); _timer = new Timer(SendMessage, null, 250, 250); Thread.Sleep(Timeout.Infinite);

Then

byte[] command = { motor1Direction, motor2Direction, motor1Speed, motor2Speed };

_module.SendTo(_RobotAddress, command);

After trialling the robot round the house I added a timer to shut the motors down if connectivity was lost. Before adding the noise suppression capacitors I managed to plough the robot into the wall when the radio link failed and the motors were running at close to full speed.

Timer CommunicationsMonitorTimer = newTimer(CommunicationsMonitorTimerProc, null, 500, 500);

void CommunicationsMonitorTimerProc(object status)

{

if (( DateTime.UtcNow - _MessageLastReceivedAt ) > MessageMaximumInterval)

{

Debug.Print("Communications timeout");

M1Speed.DutyCycle = 0.0;

M2Speed.DutyCycle = 0.0;

}

}