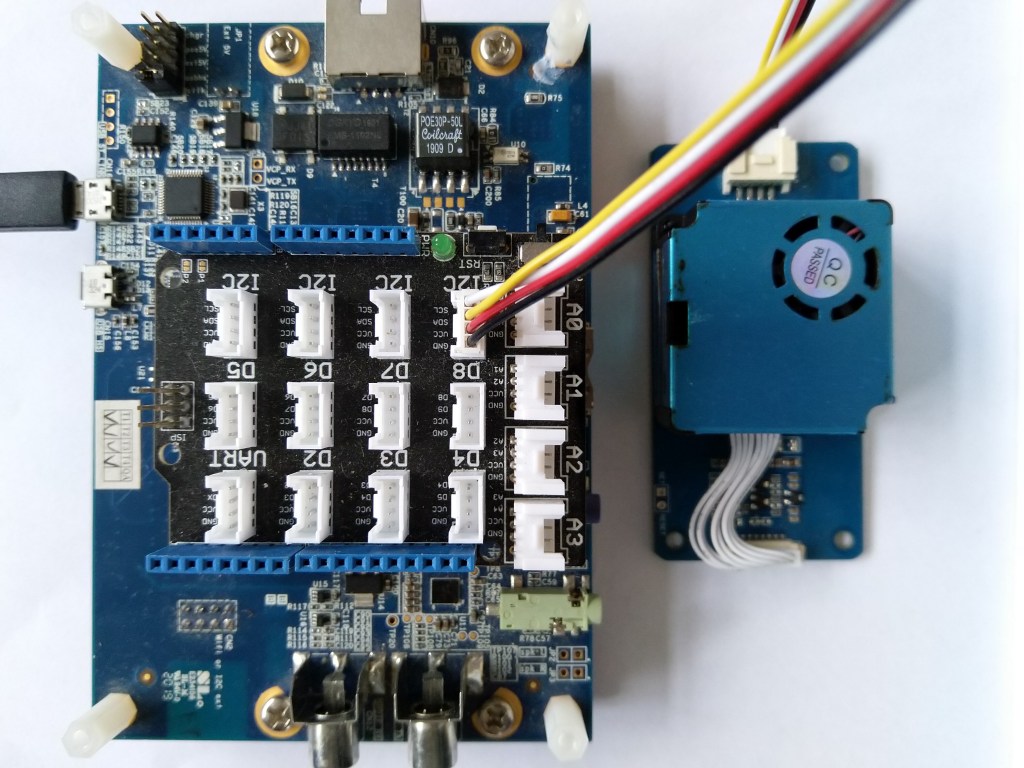

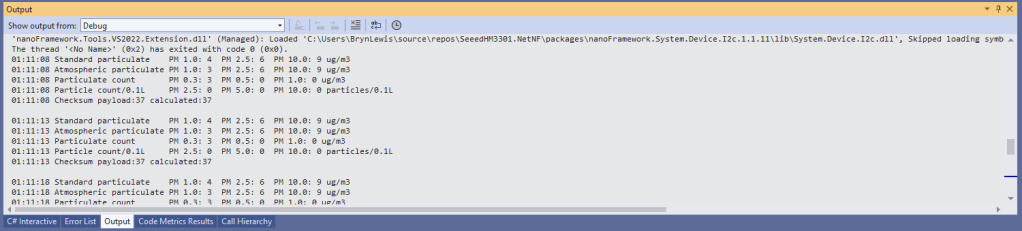

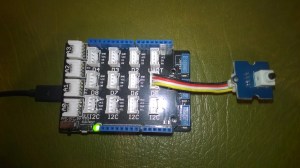

The source code of my .NET nanoFramework Seeedstudio Grove – Laser PM2.5 Dust Sensor HM3301 library is now available on GitHub. I have tested the library and sample application with Sparkfun Thing Plus and ST Micro STM32F7691 Discovery devices. (I can validate on more platform configurations if there is interest).

Important: make sure you setup the I2C pins especially on ESP32 Devices before creating the I2cDevice,

The .NET nanoFramework device libraries use a TryGet… pattern to retrieve sensor values, this library throws an exception if reading a sensor value fails. I’m not certain which approach is “better” as reading the Seeedstudio Grove – Laser PM2.5 Dust Sensor has never failed. The only time reading the “values” buffer failed was when I unplugged the device which I think is “exceptional”.

//---------------------------------------------------------------------------------

// Copyright (c) April 2023, devMobile Software

//

// Licensed under the Apache License, Version 2.0 (the "License");

// you may not use this file except in compliance with the License.

// You may obtain a copy of the License at

//

// http://www.apache.org/licenses/LICENSE-2.0

//

// Unless required by applicable law or agreed to in writing, software

// distributed under the License is distributed on an "AS IS" BASIS,

// WITHOUT WARRANTIES OR CONDITIONS OF ANY KIND, either express or implied.

// See the License for the specific language governing permissions and

// limitations under the License.

//

// nanoff --target ST_STM32F769I_DISCOVERY --update

// nanoff --platform ESP32 --serialport COM7 --update

//

//---------------------------------------------------------------------------------

#define ST_STM32F769I_DISCOVERY

//#define SPARKFUN_ESP32_THING_PLUS

namespace devMobile.IoT.Device.SeeedstudioHM3301

{

using System;

using System.Device.I2c;

using System.Threading;

#if SPARKFUN_ESP32_THING_PLUS

using nanoFramework.Hardware.Esp32;

#endif

class Program

{

static void Main(string[] args)

{

const int busId = 1;

Thread.Sleep(5000);

#if SPARKFUN_ESP32_THING_PLUS

Configuration.SetPinFunction(Gpio.IO23, DeviceFunction.I2C1_DATA);

Configuration.SetPinFunction(Gpio.IO22, DeviceFunction.I2C1_CLOCK);

#endif

I2cConnectionSettings i2cConnectionSettings = new(busId, SeeedstudioHM3301.DefaultI2cAddress);

using I2cDevice i2cDevice = I2cDevice.Create(i2cConnectionSettings);

{

using (SeeedstudioHM3301 seeedstudioHM3301 = new SeeedstudioHM3301(i2cDevice))

{

while (true)

{

SeeedstudioHM3301.ParticulateMeasurements particulateMeasurements = seeedstudioHM3301.Read();

Console.WriteLine($"Standard PM1.0: {particulateMeasurements.Standard.PM1_0} ug/m3 PM2.5: {particulateMeasurements.Standard.PM2_5} ug/m3 PM10.0: {particulateMeasurements.Standard.PM10_0} ug/m3 ");

Console.WriteLine($"Atmospheric PM1.0: {particulateMeasurements.Atmospheric.PM1_0} ug/m3 PM2.5: {particulateMeasurements.Atmospheric.PM2_5} ug/m3 PM10.0: {particulateMeasurements.Standard.PM10_0} ug/m3");

// Always 0, checked payload so not a conversion issue. will check in Seeedstudio forums

// Console.WriteLine($"Count 0.3um: {particulateMeasurements.Count.Diameter0_3}/l 0.5um: {particulateMeasurements.Count.Diameter0_5} /l 1.0um : {particulateMeasurements.Count.Diameter1_0}/l 2.5um : {particulateMeasurements.Count.Diameter2_5}/l 5.0um : {particulateMeasurements.Count.Diameter5_0}/l 10.0um : {particulateMeasurements.Count.Diameter10_0}/l");

Thread.Sleep(new TimeSpan(0,1,0));

}

}

}

}

}

}

I’m going to soak test the library for a week to check that is working okay, then most probably refactor the code so it can be added to the nanoFramework IoT.Device Library repository.