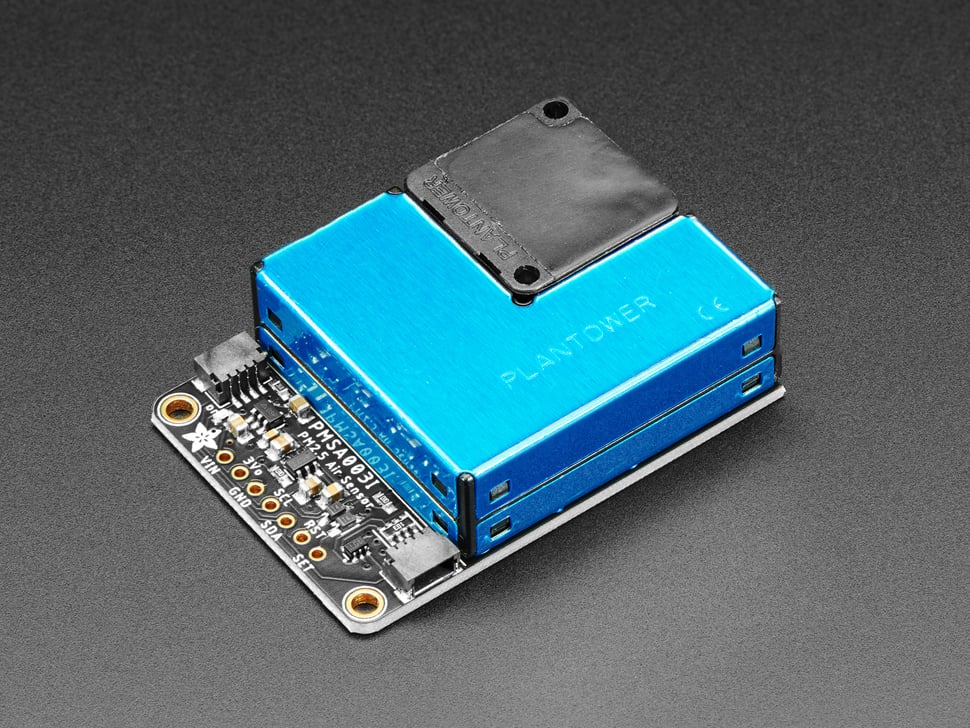

This is a “throw away” .NET nanoFramework application for investigating how Adafruit PMSA003I Inter Integrated Circuit bus(I²C) connectivity works.

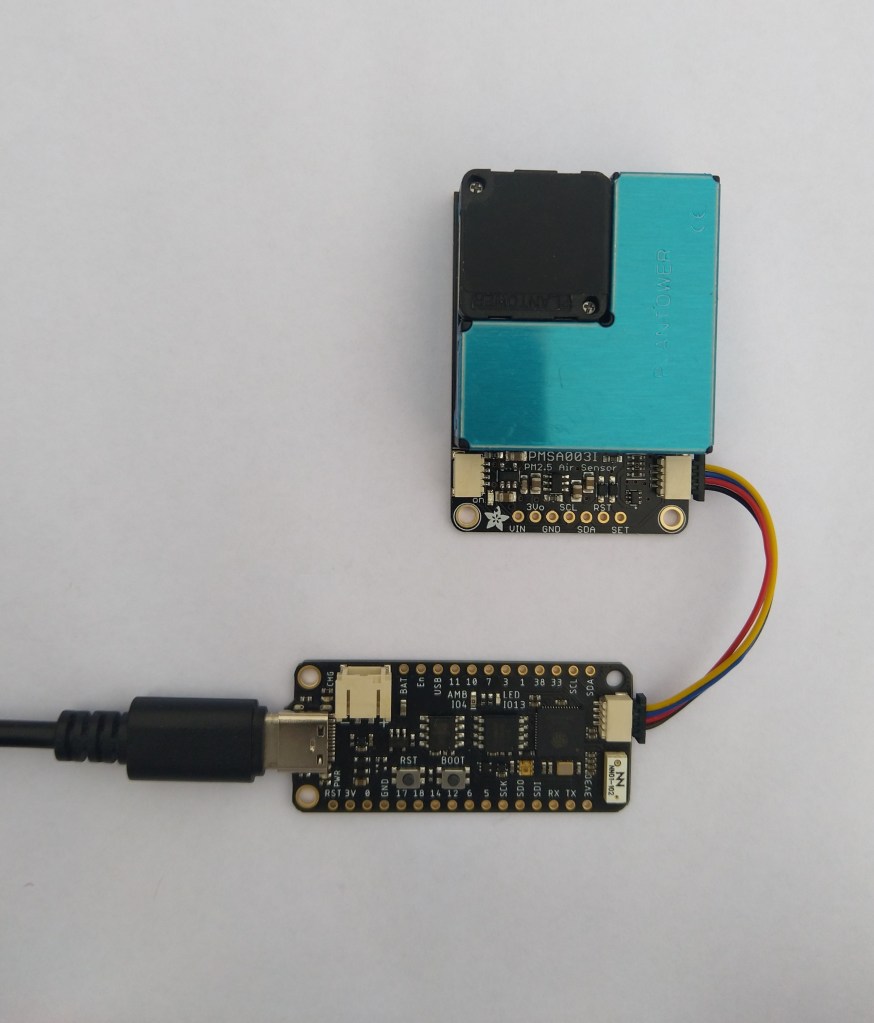

My test setup is a simple .NET nanoFramework console application running on an Adafruit FeatherS2- ESP32-S2.

The PMSA0031 application has lots of magic numbers from the PMSA003I Module Datasheet and is just a tool for exploring how the sensor works.

public static void Main()

{

#if SPARKFUN_ESP32_THING_PLUS

Configuration.SetPinFunction(Gpio.IO23, DeviceFunction.I2C1_DATA);

Configuration.SetPinFunction(Gpio.IO22, DeviceFunction.I2C1_CLOCK);

#endif

#if ADAFRUIT_FEATHER_S2

Configuration.SetPinFunction(Gpio.IO08, DeviceFunction.I2C1_DATA);

Configuration.SetPinFunction(Gpio.IO09, DeviceFunction.I2C1_CLOCK);

#endif

Thread.Sleep(1000);

I2cConnectionSettings i2cConnectionSettings = new(1, 0x12, I2cBusSpeed.StandardMode);

using (I2cDevice i2cDevice = I2cDevice.Create(i2cConnectionSettings))

{

{

SpanByte writeBuffer = new byte[1];

SpanByte readBuffer = new byte[1];

writeBuffer[0] = 0x0;

i2cDevice.WriteRead(writeBuffer, readBuffer);

Console.WriteLine($"0x0 {readBuffer[0]:X2}");

}

while (true)

{

SpanByte writeBuffer = new byte[1];

SpanByte readBuffer = new byte[32];

writeBuffer[0] = 0x0;

i2cDevice.WriteRead(writeBuffer, readBuffer);

//Console.WriteLine(System.BitConverter.ToString(readBuffer.ToArray()));

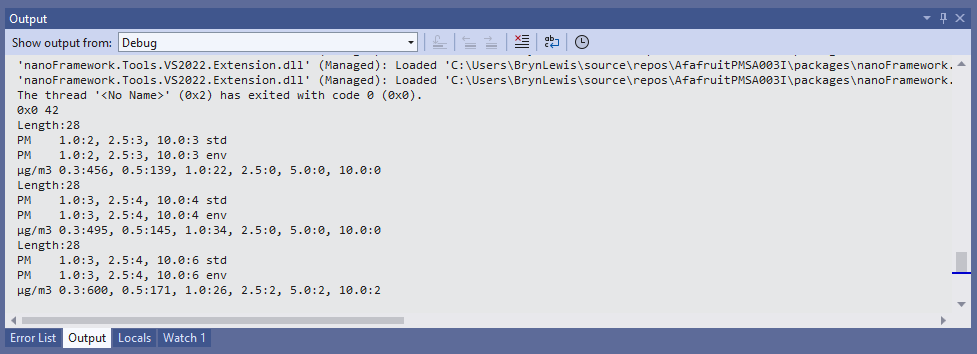

Console.WriteLine($"Length:{ReadInt16BigEndian(readBuffer.Slice(0x2, 2))}");

if ((readBuffer[0] == 0x42) || (readBuffer[1] == 0x4d))

{

Console.WriteLine($"PM 1.0:{ReadInt16BigEndian(readBuffer.Slice(0x4, 2))}, 2.5:{ReadInt16BigEndian(readBuffer.Slice(0x6, 2))}, 10.0:{ReadInt16BigEndian(readBuffer.Slice(0x8, 2))} std");

Console.WriteLine($"PM 1.0:{ReadInt16BigEndian(readBuffer.Slice(0x0A, 2))}, 2.5:{ReadInt16BigEndian(readBuffer.Slice(0x0C, 2))}, 10.0:{ReadInt16BigEndian(readBuffer.Slice(0x0E, 2))} env");

Console.WriteLine($"µg/m3 0.3:{ReadInt16BigEndian(readBuffer.Slice(0x10, 2))}, 0.5:{ReadInt16BigEndian(readBuffer.Slice(0x12, 2))}, 1.0:{ReadInt16BigEndian(readBuffer.Slice(0x14, 2))}, 2.5:{ReadInt16BigEndian(readBuffer.Slice(0x16, 2))}, 5.0:{ReadInt16BigEndian(readBuffer.Slice(0x18, 2))}, 10.0:{ReadInt16BigEndian(readBuffer.Slice(0x1A, 2))}");

// Don't need to display these values everytime

//Console.WriteLine($"Version:{readBuffer[0x1c]}");

//Console.WriteLine($"Error:{readBuffer[0x1d]}");

}

else

{

Console.WriteLine(".");

}

Thread.Sleep(5000);

}

}

}

private static ushort ReadInt16BigEndian(SpanByte source)

{

if (source.Length != 2)

{

throw new ArgumentOutOfRangeException();

}

ushort result = (ushort)(source[0] << 8);

return result |= source[1];

}

The unpacking of the value standard particulate, environmental particulate and particle count values is fairly repetitive, but I will fix it in the next version.

The checksum calculation isn’t great even a simple cyclic redundancy check(CRC) would be an improvement on summing the 28 bytes of the payload.