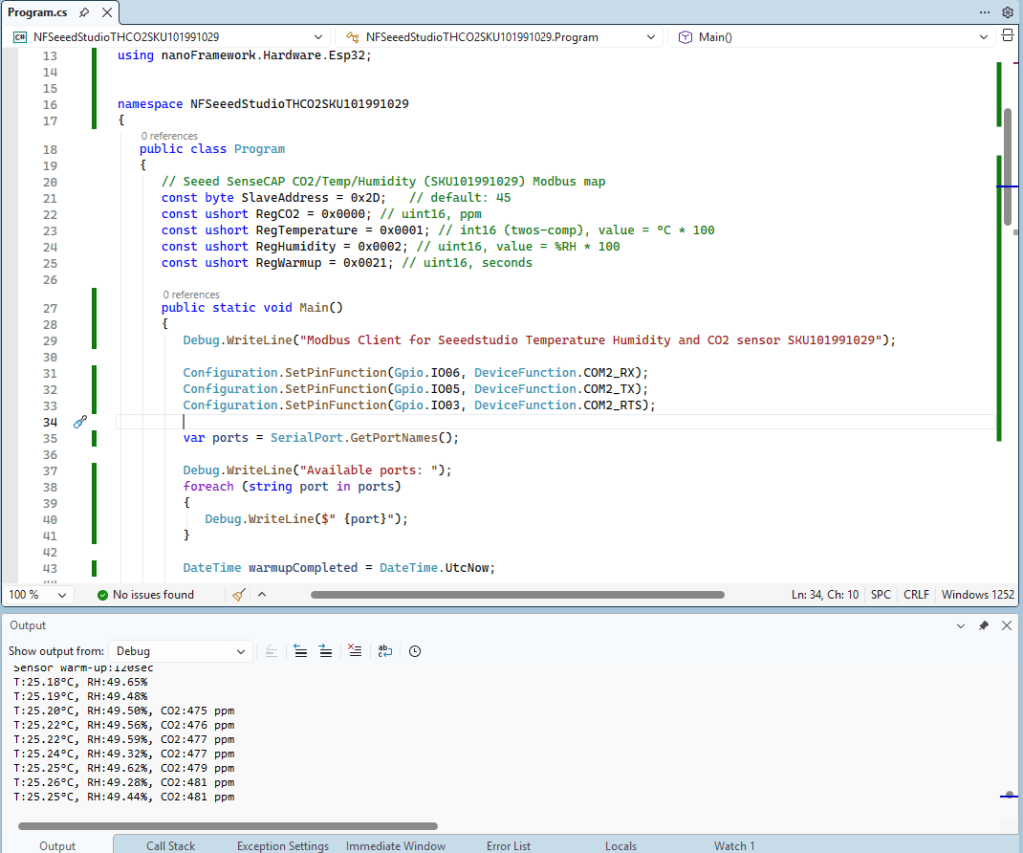

As part of this series of samples comparing Arduino to nanoFramework to .NET IoT Device “Proof of Concept (PoC) applications, several posts use a SenseCAP CO2, Temperature and Humidity Sensor SKU101991029.

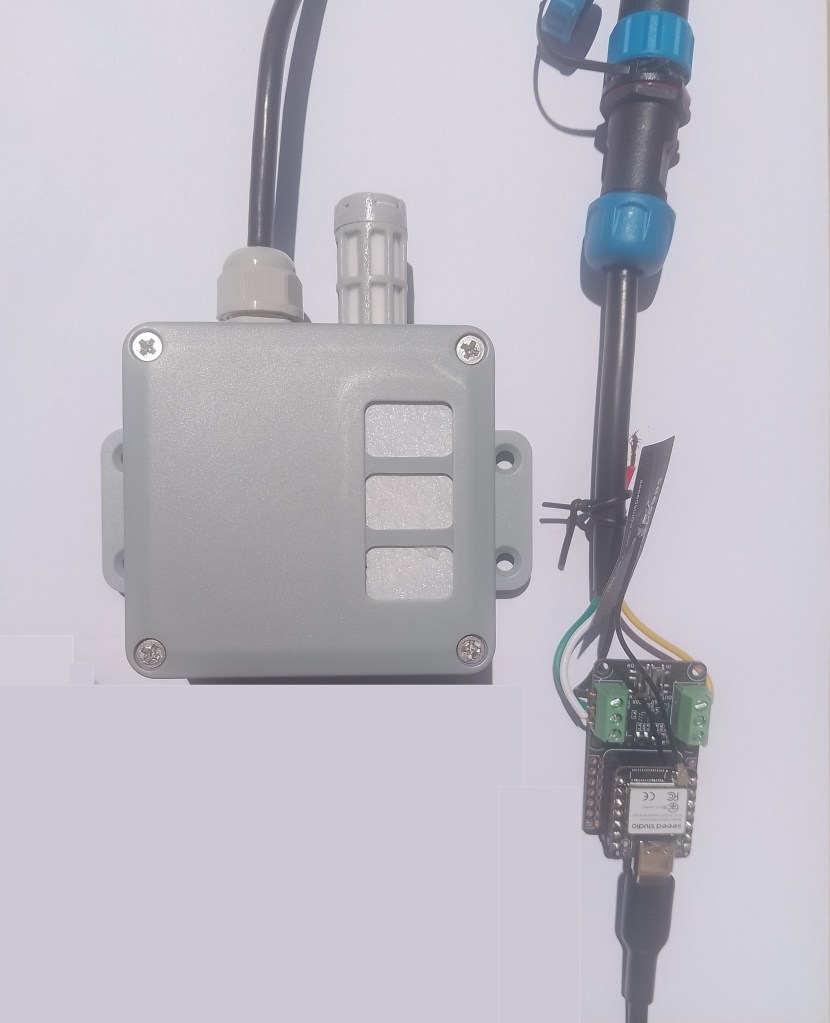

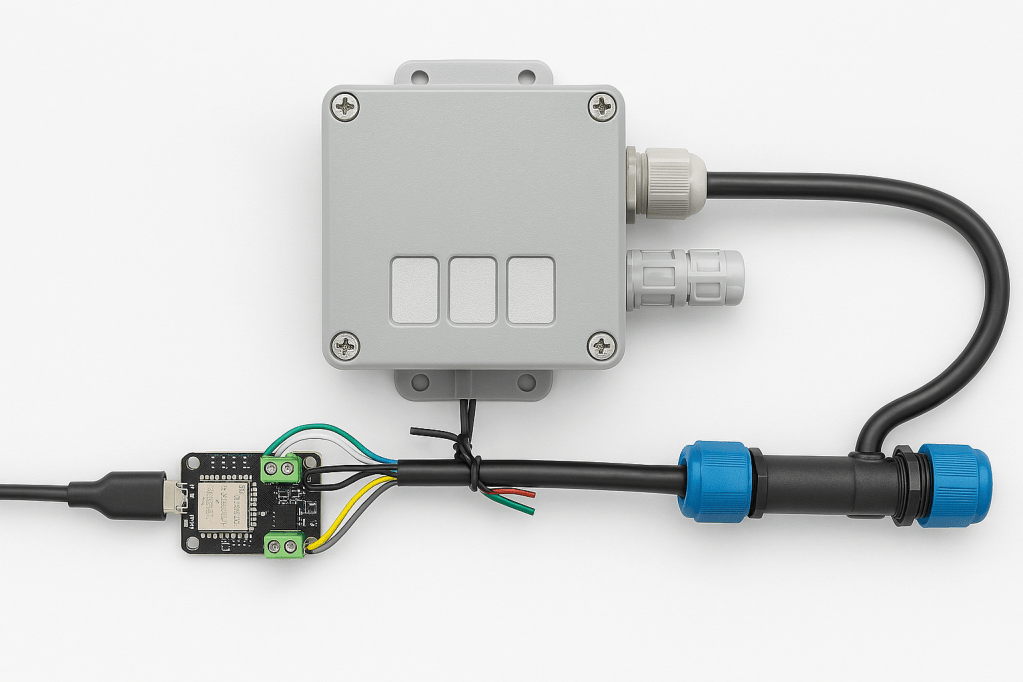

I cut up a spare Industrial IP68 Modbus RS485 1-to-4 Splitter/Hub to connect the sensor to the breakout board. This sensor has an operating voltage of 5V ~ 24V so it can be powered by the 5V output of a RS485 Breakout Board for Seeed Studio XIAO (SKU 113991354)

The red wire is for powering the sensor with a 12V power supply so was tied back so it didn’t touch any of the other electronics.

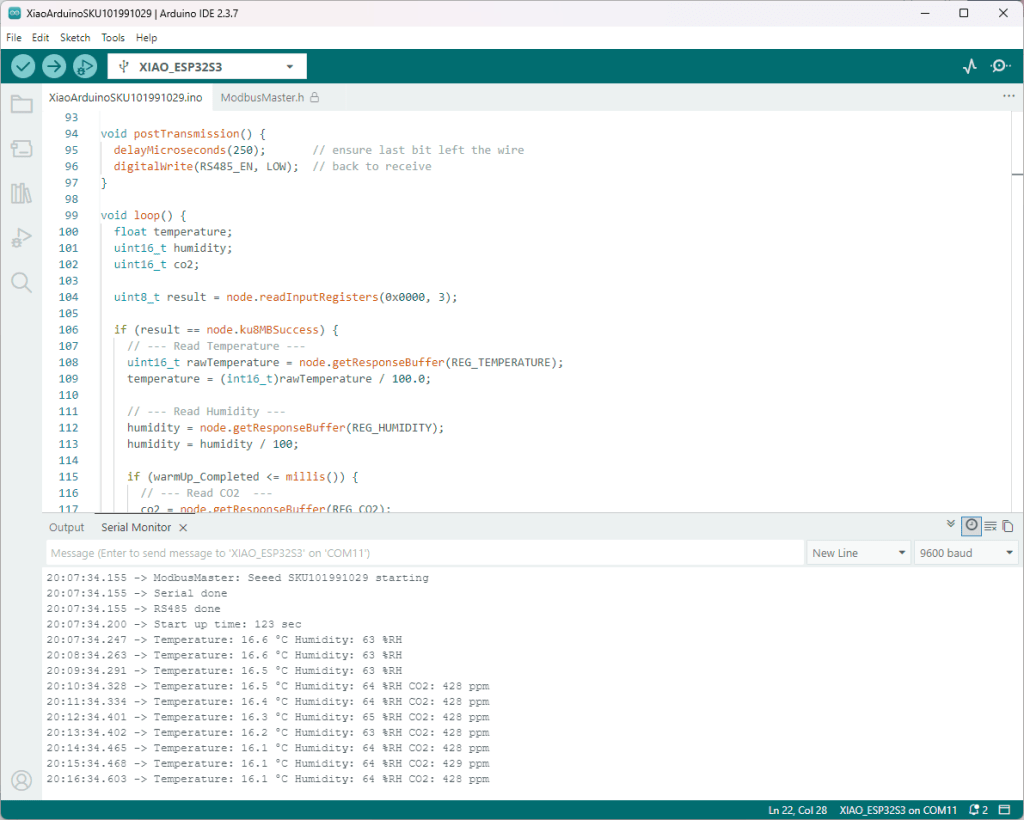

#include <HardwareSerial.h>

#include <ModbusMaster.h>

HardwareSerial RS485Serial(1);

ModbusMaster node;

// -----------------------------

// RS485 Pin Assignments (Corrected)

// -----------------------------

const int RS485_RX = 6; // UART1 RX

const int RS485_TX = 5; // UART1 TX

const int RS485_EN = D2;

// Sensor/Modbus parameters (from datasheet)

#define MODBUS_SLAVE_ID 0x2D

#define REG_CO2 0x0000

#define REG_TEMPERATURE 0x0001

#define REG_HUMIDITY 0x0002

#define REG_WARMUP_TIME 0x0021

uint32_t warmUp_Completed;

// Forward declarations for ModbusMaster callbacks

void preTransmission();

void postTransmission();

void setup() {

Serial.begin(9600);

delay(5000);

Serial.println("ModbusMaster: Seeed SKU101991029 starting");

// Wait for the hardware serial to be ready

while (!Serial)

;

Serial.println("Serial done");

pinMode(RS485_EN, OUTPUT);

digitalWrite(RS485_EN, LOW); // Start in RX mode

// Datasheet: 9600 baud, 8N1

RS485Serial.begin(9600, SERIAL_8N1, RS485_RX, RS485_TX);

while (!RS485Serial)

;

Serial.println("RS485 done");

// Tie ModbusMaster to the UART we just configured

node.begin(MODBUS_SLAVE_ID, RS485Serial);

// Register callbacks for half-duplex direction control

node.preTransmission(preTransmission);

node.postTransmission(postTransmission);

// --- Read Startup time ---

uint8_t result = node.readHoldingRegisters(REG_WARMUP_TIME, 1);

if (result == node.ku8MBSuccess) {

uint16_t warmUpTime = node.getResponseBuffer(0);

warmUpTime += 3;

Serial.printf("Start up time: %u sec\n", warmUpTime);

warmUp_Completed = millis() + (warmUpTime * 1000);

} else {

Serial.printf("Read REG_WARMUP_TIME failed (err=%u)\n", result);

}

}

// Toggle DE/RE around TX per ModbusMaster design

void preTransmission() {

digitalWrite(RS485_EN, HIGH); // enable driver (TX)

delayMicroseconds(250); // transceiver turn-around margin

}

void postTransmission() {

delayMicroseconds(250); // ensure last bit left the wire

digitalWrite(RS485_EN, LOW); // back to receive

}

void loop() {

float temperature;

uint16_t humidity;

uint16_t co2;

uint8_t result = node.readInputRegisters(0x0000, 3);

if (result == node.ku8MBSuccess) {

// --- Read Temperature ---

uint16_t rawTemperature = node.getResponseBuffer(REG_TEMPERATURE);

temperature = (int16_t)rawTemperature / 100.0;

// --- Read Humidity ---

humidity = node.getResponseBuffer(REG_HUMIDITY);

humidity = humidity / 100;

if (warmUp_Completed <= millis()) {

// --- Read CO2 ---

co2 = node.getResponseBuffer(REG_CO2);

Serial.printf("Temperature: %.1f °C Humidity: %u %%RH CO2: %u ppm\n", temperature, humidity, co2);

}

else {

Serial.printf("Temperature: %.1f °C Humidity: %u %%RH\n", temperature, humidity);

}

}

else

{

Serial.printf("Modbus error: %d\n", result);

}

delay(60000);

}

The Arduino ModbusMaster based application worked first time but implementing the CO2 Sensor warm-up time took a couple of attempts.

I did consider trying to fit the Seeed Studio XIAO ESP32-S3 inside the SenseCAP CO2, Temperature and Humidity Sensor but the electronics had been sprayed with a corrosion resistant coating.

Connecting directly (rather than via a breakout board) the VCC+, VCC-, universal asynchronous receiver-transmitter(UART) and transmit enable would have been difficult.