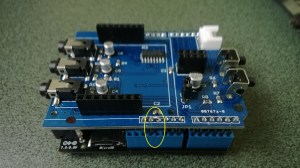

The Hardware

Flash an LED

OutputPort led = new OutputPort(Pins.ONBOARD_LED, false);

while ( true)

{

Led.Write(!Led.Read())

Thread.Sleep(500)

}

Digital Input – Polled

InputPort button = new InputPort(Pins.ONBOARD_SW1, false, Port.ResistorMode.Disabled);

OutputPort led = new OutputPort(Pins.ONBOARD_LED, false);

while (true)

{

led.Write(button.Read());

Thread.Sleep(1000);

}

Digital Input – Interrupt

static OutputPort interuptled = new OutputPort(Pins.ONBOARD_LED, false);

InterruptPort button = new InterruptPort(Pins.ONBOARD_SW1, false, Port.ResistorMode.Disabled, Port.InterruptMode.InterruptEdgeHigh);

button.OnInterrupt += new NativeEventHandler(button_OnInterrupt);

Thread.Sleep(Timeout.Infinite);

static void button_OnInterrupt(uint data1, uint data2, DateTime time)

{

interuptled.Write(!interuptled.Read());

}

Analog Input

AnalogInput Sensor = new AnalogInput(Cpu.AnalogChannel.ANALOG_0);

while ( true)

{

Debug.Print( "Value " + Sensor.Read().ToString("F2"));

Thread.Sleep(500);

}

Pulse Width Modulation Output

AnalogInput brightness = new AnalogInput(AnalogChannels.ANALOG_PIN_A0);

PWM led = new PWM(PWMChannels.PWM_PIN_D5, 1000, 0.0, false);

led.Start();

while (true)

{

Debug.Print("Brightness " + led.DutyCycle.ToString("F2"));

led.DutyCycle = brightness.Read();

Thread.Sleep(500);

}

led.Stop();

Power Consumption Monitor

- Energy Monitor Shield USD 23.00

- Non-invasive current Sensor 30A USD10.80

Developing the software for the Energy Monitor Shield

- Read the buttons using an Analog input

- Calibrate the sensor for the offset voltage

- Calculate the RMS current based on the sensor outputs and AnalogInput range

- Display the power consumption on the Nokia 5110 display

- Compensate for Noise on the AnalogInput

- Upload the power consumption information to xively

Robot

Developing the software

- Determine the distance to objects

- Control the speed & direction of the motors using a Motor Shield Driver

- Basic obstacle avoidance

- Avoid obstacles using a state machine

- Fine tune the motor speeds using a rotary encoder

- Connect the GPS

- Upload the position information to Xively

Heart Rate Monitor

Developing the software

- Read the buttons using an AnalogInput

- Count the number of button presses using an InterruptPort and a Timer

- Determine the pulse rate in BPM by counting

- Determine the average pulse rate in BPM

- Display and manage the pulse rate info on the DFRobot 16×2 Lcd Shield

- Upload the pulse rate information to xively